Ball Bearing vs Roller Bearing: Understanding How They Work and Minimize Friction

2025-04-28

Slewing ring bearings are critical components in countless machines, enabling smooth rotation and supporting significant loads. Choosing the right type – often a ball bearing or a roller bearing – is crucial for performance, longevity, and cost-effectiveness. This article dives deep into the world of ball bearings work, exploring how ball bearing and roller bearing types function, their key differences, how they reduce friction, and which applications they suit best. Understanding these fundamentals will empower you, whether you’re a design engineer or a procurement specialist like Mark Thompson, to make informed decisions and avoid common pitfalls like communication issues or receiving bearings that don’t meet specifications, ensuring your equipment operates reliably.

What Exactly is a Ball Bearing and How Does it Work?

A ball bearing is a type of rolling-element bearing that uses spherical balls to maintain the separation between the bearing races. The primary purpose of a ball bearing is to reduce friction and support loads. Think of a simple bicycle wheel hub – chances are, it uses ball bearings work to allow the wheel to spin freely around the axle. These bearings consist of several key parts: an outer ring, an inner ring, a set of steel balls (or sometimes ceramic balls), and often a cage or retainer to keep the balls evenly spaced.

The magic of how ball bearings work lies in the rolling motion. When a load is applied, it’s transmitted from the outer ring, through the steel balls, to the inner ring (or vice versa, depending on the application). Because the balls roll along the smooth, hardened surfaces of the inner and outer race (also called raceways), the rolling friction generated is significantly lower than the sliding friction you’d get if two flat surfaces rubbed directly against each other. This efficiency means less power is needed to initiate and maintain rotation. Ball bearings are essential components in countless mechanical devices.

Ball bearings are used extensively because of their ability to handle both radial load (perpendicular to the shaft) and, in many designs, axial load (parallel to the shaft, also known as thrust load). The small contact area between the spherical balls and the raceways allows them to spin at relatively high speeds with minimal heat generation. This makes ball bearings are ideal for applications where speed is a priority. However, this small contact area also means their load capacity is generally lower compared to roller bearings of the same size. Different ball bearing designs cater to specific needs, from deep-groove ball bearing types handling combined loads to angular contact ball bearing types optimized for higher axial load.

How Do Roller Bearings Differ from Ball Bearings in Design and Function?

While ball bearings use spherical balls, roller bearing types utilize cylindrical, tapered, spherical, or needle-shaped rollers as the rolling elements. This fundamental difference in shape dictates their performance characteristics. Instead of the point contact of a ball bearing, a roller bearing features line contact between the roller elements and the raceways of the inner and outer rings. This larger contact area is the key distinction.

This line contact significantly increases the surface over which the load is transmitted. As a result, roller bearing types can generally support much higher loads, particularly radial load, than a ball bearing of comparable size. This makes them suitable for applications involving heavy load conditions, such as in construction equipment, gearboxes, and industrial machinery. The roller elements distribute the stress more effectively, reducing pressure on the bearing balls and races (or rather, rollers and races in this case).

However, this larger contact area typically results in slightly higher friction compared to a ball bearing, especially at high speeds. The geometry of roller bearing designs also influences their ability to handle different load cases. Cylindrical roller bearing types excel at handling high radial load but have limited axial load capacity. Tapered roller bearing units can handle significant combined radial and axial loads. Spherical roller bearing designs are excellent for heavy radial load and can tolerate some angular misalignment. Needle roller bearing types are compact and suitable for high radial load in space-constrained applications. Unlike roller bearings, ball bearings often offer better high-speed performance due to lower friction.

Ball Bearing vs Roller Bearing: Which Handles Higher Loads More Effectively?

When it comes to pure load capacity, roller bearing types generally have the upper hand over ball bearing types. This is a direct consequence of the contact mechanics we discussed. A ball bearing makes point contact with the inner and outer race, concentrating the load onto a very small contact area. Think of balancing a bowling ball on your fingertip – all the weight is focused on one tiny spot.

In contrast, a roller bearing makes line contact. Imagine laying a rolling pin on a countertop – the weight is distributed along the length of the roller. This larger contact area in a roller bearing allows it to distribute the applied force over a wider surface, significantly reducing the stress within the bearing. Consequently, for applications demanding the ability to support substantial radial load or combined higher loads, engineers often specify roller bearings to take the brunt of the force.

This doesn’t mean ball bearings are weak; specific designs like angular contact ball bearing pairs or double-row ball bearing units can handle considerable loads. However, on a size-for-size basis, particularly for heavy radial load, the roller bearing is typically the more robust choice. If your primary concern is maximizing the ability to handle a heavy load, a roller bearing is often the first consideration. The choice between ball or roller bearings heavily depends on the specific load requirements of the application.

"In our experience manufacturing slewing rings for heavy equipment, the choice between ball and roller elements is critical. For large excavators or cranes where massive radial and moment loads are common, three-row roller bearings or cross roller bearings are often necessary to provide the required capacity and rigidity." – Allen, Xinda Slewing Bearing Expert

Understanding Radial vs. Axial Load: Which Bearing Type Excels Where?

Loads on bearings rarely come in just one direction. They are typically classified as radial load (acting perpendicular to the shaft axis, like the weight supported by a wheel axle) or axial load (acting parallel to the shaft axis, also called thrust load, like the force on a drill bit). Many applications involve a combination of both radial and axial loads. Understanding how ball bearing and roller bearing types handle these different forces is key to proper selection.

Standard deep-groove ball bearing types are remarkably versatile. They can handle moderate radial load and also a fair amount of axial load in either direction, thanks to the geometry of their raceways. This makes the common single-row ball bearing a popular choice for a wide range of applications. Angular contact ball bearing types are specifically designed to handle higher combined radial and axial loads, often used in pairs to manage thrust in both directions. Thrust bearings using balls are designed primarily for axial load.

Roller bearing types exhibit more specialized behavior regarding load direction.

- Cylindrical Roller Bearings: Excellent for high radial load, but most designs accommodate little to no axial load.

- Tapered Roller Bearings: Can support significant radial load and axial load in one direction. Often used in pairs (back-to-back or face-to-face) to handle axial loads in both directions.

- Spherical Roller Bearings: Designed for very high radial load and moderate axial load in both directions. Their key advantage is accommodating misalignment between the shaft and housing.

- Needle Roller Bearings: Primarily handle high radial load in compact spaces; limited axial load capacity.

- Roller Thrust Bearings: Specifically designed to take axial loads, similar to ball thrust bearings but with higher load capacity.

Therefore, if an application involves primarily radial load, a cylindrical roller bearing or a deep-groove ball bearing might suffice. If significant axial load is present alongside radial load, tapered roller bearing or angular contact ball bearing types become contenders. For pure thrust, dedicated thrust bearings (either ball bearing or roller bearing type) are the answer. The ability to handle radial and thrust loads varies greatly among the different types of bearings.

The Science of Smoothness: How Do Bearings Reduce Friction?

The fundamental purpose of any rolling-element bearing, whether it’s a ball bearing or a roller bearing, is to reduce friction between moving parts. Imagine trying to spin a heavy shaft directly within a housing – the sliding friction would be immense, requiring significant force and generating excessive heat and wear. Bearings replace this high sliding friction with much lower rolling friction.

How ball bearings work to achieve this, and similarly roller bearings, involves the principle of tribology – the science of interacting surfaces in relative motion. Instead of large surfaces rubbing together, the load is transferred through rolling elements (steel balls or rollers) that roll along hardened raceways on the inner and outer rings. Because rolling requires overcoming less resistance than sliding, the overall friction is dramatically reduced. This mechanism reduces the friction significantly, allowing components to rotate easily.

Several factors contribute to the low friction in bearings:

- Rolling Motion: The primary mechanism for reducing friction.

- Smooth Surfaces: The balls/rollers and the raceways are manufactured to high precision with extremely smooth surfaces to minimize resistance.

- Hard Materials: Using hardened steel or ceramics ensures the rolling elements and raceways maintain their shape under load and resist wear, preventing increases in friction over time.

- Lubrication: A thin film of grease or oil separates the rolling elements from the raceways at the microscopic level, further preventing direct metal-to-metal contact and reducing rolling resistance.

While both ball bearing and roller bearing types drastically reduce friction compared to plain bearings, ball bearings typically exhibit less friction (or lower friction) than roller bearings due to their smaller contact area (point contact vs. line contact). This makes ball bearings are ideal for high-speed applications where minimizing friction and heat generation is paramount. The goal is always to minimize friction for efficient operation.

Lubrication Matters: Why Grease and Oil Are Vital for Bearing Life?

Lubrication is not just an optional extra for bearings; it’s absolutely essential for their proper function and longevity. Whether using a ball bearing or a roller bearing, the lubricant performs several critical tasks that go far beyond simply making things slippery. Without adequate lubrication, even the best bearing will fail prematurely due to excessive friction, heat, and wear.

Key functions of lubrication (grease or oil) in bearings include:

- Reducing Friction: Creates a thin film separating rolling elements (metal ball or roller) from the raceways, minimizing direct contact and rolling friction.

- Preventing Wear: The lubricant film cushions the contact points, reducing wear on the precision surfaces of the bearing balls and races.

- Heat Dissipation: Helps to carry away heat generated by friction within the bearing, preventing overheating.

- Corrosion Protection: Shields bearing surfaces from moisture and contaminants that could cause rust or corrosion.

- Contaminant Exclusion: Grease, in particular, can help form a barrier, preventing dirt and debris from entering the bearing.

The choice between grease and oil depends on the application. Grease is essentially a base oil thickened with a soap or non-soap agent. It’s easier to retain within the bearing, provides good sealing against contaminants, and requires less frequent replenishment, making it the most common choice for ball bearing and roller bearing types in many applications. Oil lubrication is often preferred for very high speeds or high temperatures where heat dissipation is critical, or where a central lubrication system exists (e.g., in a gearbox). The correct oil viscosity or grease consistency is crucial for forming an effective lubricating film. Bearing manufacturers provide guidance on appropriate lubrication selection. Insufficient or improper lubrication is a leading cause of bearing failure. Using the right grease ensures long life.

Key Applications: Where Are Ball and Roller Bearings Used in Many Industries?

The versatility and efficiency of ball bearing and roller bearing types mean they are ubiquitous across many industries and multiple industries. Their ability to facilitate smooth rotation, support loads, and reduce friction makes them indispensable in countless mechanical devices. Here’s a glimpse into their diverse bearing uses:

Ball Bearing Applications:

- Automotive: Wheel hubs (often angular contact), transmissions, alternators, electric motors.

- Aerospace: Instrument panels, control systems, engines (specialized high-speed bearings).

- Electric Motors & Fans: Supporting rotating shafts at high speeds with low friction.

- Bicycles: Wheel hubs, bottom brackets, steering heads.

- Hard Disk Drives: Spindle motors requiring precise, low-friction rotation.

- Skateboards & Roller Skates: Small ball bearing units allow wheels to spin faster.

- Light Industrial Machinery: Conveyor rollers, small gearboxes.

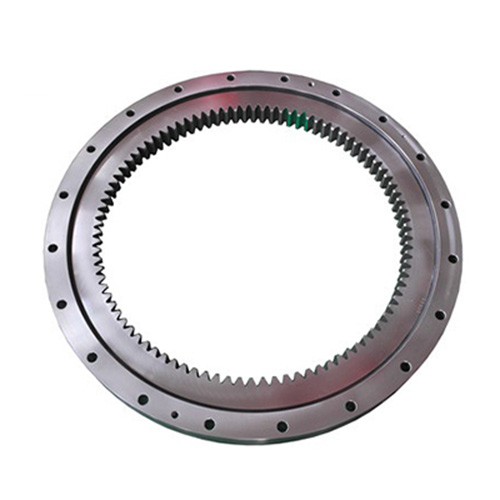

- Light Type & Flange Slewing Ring Bearings: Often utilize ball elements for applications requiring moderate load capacity and smooth movement.

Roller Bearing Applications:

- Heavy Construction Equipment: Excavator turntables (Three Row -Roller Bearing Slewing Bearings often use multiple rows of rollers), crane hooks, bulldozer track rollers (handling immense radial load and heavy load).

- Industrial Gearboxes: Supporting shafts under high torque and heavy load.

- Wind Turbines: Main shaft bearings, pitch and yaw mechanisms (often large diameter roller bearing types).

- Railway Axle Boxes: Supporting the weight of train cars (heavy radial load).

- Rolling Mills: Supporting massive rollers used in metal forming.

- Agricultural Machinery: Harvesters, tractors, implements subjected to heavy load and harsh conditions.

- Mining Equipment: Crushers, conveyors, and other machinery operating under extreme loads.

- Single Row- Rollers Bearing Slewing Rings: Common in applications requiring higher load capacity than single-row ball bearings.

Essentially, anywhere a shaft needs to rotate relative to a stationary housing while supporting a load, you’ll likely find either ball or roller bearings hard at work. Bearings are also available in specialized configurations for unique load cases.

Speed vs. Load: Selecting the Right Bearing for High-Speed Applications?

The relationship between speed and load capacity is often a trade-off when selecting bearings. Generally, bearings designed for very high speeds may not have the same load capacity as those designed for heavy load at lower speeds, and vice versa. Understanding this balance is crucial for high-speed applications.

Ball bearings are ideal for higher speeds primarily because they generate less friction than roller bearing types. The point contact between the metal ball and the raceways results in lower rolling resistance and less heat generation as rotational speeds increase. This allows ball bearings to spin faster without overheating or premature failure, provided they are properly lubricated with the correct grease or oil. Precision ball bearing types, often using ceramic (steel or ceramic) balls and specialized cage designs, are used in ultra-high-speed applications like machine tool spindles and dental drills.

Roller bearing types, with their larger line contact area, inherently generate more friction and heat at high speeds. While certain cylindrical roller bearing designs can operate at relatively high speeds, they generally have lower speed limits compared to ball bearing types of similar size. The limiting factor is often the heat generated by friction between the moving parts, which can degrade the lubrication and damage the bearing supports. However, for applications requiring both high load capacity and moderate to high speeds, specialized roller bearing designs and careful lubrication management are employed. For very heavy load scenarios, speed bearings might need to be significantly larger or use specialized cooling systems.

Therefore, for applications prioritizing maximum rotational speed with moderate loads, a ball bearing is often the preferred choice. For applications involving higher loads where speed is secondary, a roller bearing is typically more suitable. The selection involves analyzing the specific speed (RPM), load (radial, axial, or combined), and operating temperature requirements.

Material Considerations: Steel, Ceramic, and Other Options for Ball Bearings and Roller Bearings?

The materials used for the rings (inner and outer rings) and rolling elements (steel balls or rollers) significantly impact a bearing’s performance, durability, cost, and suitability for specific environments. While standard bearings typically use chromium steel, other materials offer distinct advantages.

- Chromium Steel (e.g., 52100): This is the workhorse material for most ball bearing and roller bearing types. It offers an excellent balance of hardness, wear resistance, fatigue life, and cost-effectiveness after heat treatment. It’s suitable for a vast range of general-purpose applications.

- Stainless Steel (e.g., 440C): Used when corrosion resistance is required, such as in food processing, medical, or marine applications. Stainless steel balls and rings resist rust and degradation from moisture or mild chemicals, though they might have slightly lower load capacity and hardness compared to chromium steel.

- Ceramic (e.g., Silicon Nitride – Si3N4): Ceramic balls (steel or ceramic) offer several advantages, particularly in high-speed applications or harsh environments. They are lighter, harder, smoother, and have a lower coefficient of thermal expansion than steel. This results in less friction, higher speed capabilities, longer life, and better performance with marginal lubrication. They are also electrically insulating. Hybrid bearings (ceramic balls, steel rings) are common. Full ceramic bearings are used in highly specialized, corrosive, or non-magnetic applications but are significantly more expensive and can be more brittle (more liable to crack under shock loads).

- Plastics & Polymers: Used in low-load, low-speed, or highly corrosive environments where metal bearings are unsuitable. They are lightweight, self-lubricating (sometimes), and corrosion-proof but have much lower load capacity and temperature limits.

The choice of material depends on factors like operating temperature, speed, load, required lifespan, environmental conditions (corrosion, magnetism), and budget. Standard steel balls and rings are adequate for most situations, but demanding applications may necessitate stainless steel or ceramic components. We, as bearing manufacturers, can guide you on material selection based on your specific bearing uses. Choosing the right material for the outer and inner rings and rolling elements is critical.

Partnering for Success: Why Choosing the Right Bearing Manufacturer is Crucial?

Selecting the right ball bearing or roller bearing type is only part of the equation. Partnering with a reliable and experienced bearing manufacturer, like us at Xinda Slewing Bearing, is equally critical, especially for procurement professionals like Mark Thompson who value quality, communication, and dependability. The wrong supplier can lead to significant pain points: communication breakdowns, delayed shipments disrupting production, and receiving bearings that fail to meet critical specifications for load capacity or dimensions.

A reputable manufacturer offers more than just a product; they provide partnership and expertise. Here’s what to look for:

- Technical Expertise: Ability to understand your application’s requirements (radial load, axial load, speed, environment) and recommend the optimal ball bearing or roller bearing solution, including material selection and lubrication advice. We can help ensure the load is transmitted effectively and safely.

- Quality Assurance: Robust quality control processes, material certifications, and adherence to international standards (like ISO) to guarantee dimensional accuracy, load capacity verification, and consistent performance. This prevents premature failures and ensures the bearing supports the intended load capacity.

- Customization Capabilities: Flexibility to design and manufacture non-standard or specialized bearings if required, including specific gearbox integrations or unique sealing arrangements. We offer Inch size Slewing Ring Bearings and custom designs.

- Clear Communication: Responsive sales and engineering teams who can provide clear technical information, answer questions promptly, and keep you informed about production progress and lead times. This addresses the common pain point of inefficient communication.

- Reliable Lead Times: Transparent and dependable production schedules to help you manage your inventory and manufacturing timelines effectively, avoiding costly delays.

- Comprehensive Product Range: Offering a wide array of types of bearings, including single-row ball bearing, roller bearing (cylindrical, spherical, tapered), thrust bearings, and specialized slewing rings, allows for a single-source solution.

As a factory specializing in slewing rings and bearings, exporting globally to demanding markets like the USA, Europe, and Australia, we understand these needs. We invest in our production lines and quality control to deliver bearings – from standard ball bearing units to complex three row -roller bearing slewing bearings – that meet stringent requirements and provide long service life, ensuring smooth rotation and reliable operation for your equipment.

Key Takeaways: Ball Bearing vs. Roller Bearing

- Function: Both ball bearing and roller bearing types reduce friction between moving parts using rolling elements (sphere vs. roller) instead of sliding contact.

- Contact: Ball bearings have point contact (smaller contact area), while roller bearings have line contact (larger contact area).

- Load Capacity: Roller bearing types generally handle higher loads (especially radial load) due to larger contact area. Ball bearings are suitable for moderate loads.

- Speed: Ball bearings typically offer lower friction and higher speed capabilities (high-speed applications).

- Load Direction: Deep-groove ball bearings handle combined radial and axial loads well. Roller bearing types are often more specialized (e.g., cylindrical for radial, tapered for combined radial and axial, thrust for axial load).

- Friction: Ball bearings generally exhibit less friction/lower friction than roller bearings.

- Lubrication: Essential (grease or oil) for reducing friction, preventing wear, dissipating heat, and protecting against corrosion in both types of bearings.

- Applications: Ball bearings are used widely where speed and moderate loads are key (motors, wheels). Roller bearings dominate heavy load applications (construction, gearboxes).

- Manufacturer Choice: Partnering with a knowledgeable and reliable bearing manufacturer is crucial for quality, communication, and on-time delivery.

Understanding these differences between ball bearing and roller bearing designs empowers you to select the most effective solution for your specific needs, ensuring optimal performance and longevity for your machinery.