Detailed Guide to Different Kinds of Slewing Bearings

2024-08-27

Slewing bearings, also known as slewing rings or turntable bearings, are versatile and essential components used in a wide range of machinery and equipment, from cranes and excavators to wind turbines and robotics. These bearings are designed to support axial, radial, and moment loads, making them ideal for applications that require rotational movement. Understanding the different kinds of slewing bearings and their specific uses is crucial for selecting the right bearing for any application. This guide will explore the various types of slewing bearings, their characteristics, and their best use cases.

1. Single-Row Ball Slewing Bearings

Single-row ball slewing bearings consist of a single row of balls housed between an inner and outer ring. These bearings are compact and lightweight, making them suitable for applications where space is limited and weight is a concern.

- Characteristics: They offer low friction and high-speed capabilities, which are ideal for applications where rotational speed is more critical than load-bearing capacity. They typically have an open structure, meaning they are easy to assemble and disassemble.

- Applications: Single-row ball slewing bearings are commonly used in light-duty applications such as small cranes, aerial work platforms, and rotating tables where lower loads and higher rotational speeds are required.

2. Double-Row Ball Slewing Bearings

Double-row ball slewing bearings feature two rows of ball bearings, providing a higher load-carrying capacity than single-row designs. The dual-row configuration allows these bearings to manage larger axial, radial, and moment loads.

- Characteristics: These bearings are more robust than their single-row counterparts and can accommodate greater loads while maintaining smooth operation. They also offer increased stability due to the dual ball rows.

- Applications: Double-row ball slewing bearings are ideal for medium-duty applications such as medium-sized cranes, excavators, and tower cranes, where higher load capacities and stability are essential.

3. Single-Row Cross Roller Slewing Bearings

Single-row cross roller slewing bearings are designed with cylindrical rollers arranged in a crisscross pattern. This unique arrangement allows the bearing to handle high axial and radial loads as well as tilting moments with high rigidity.

- Characteristics: Cross roller bearings provide excellent load distribution and high stiffness, which enhances their ability to withstand shock loads and maintain precision. They have a compact design, making them suitable for applications where space is limited.

- Applications: These bearings are commonly used in precision equipment such as robotics, medical devices, and machine tools, where both high load capacity and precise rotational accuracy are required.

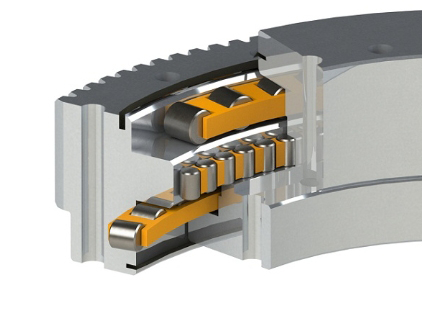

4. Double-Row Roller Slewing Bearings

Double-row roller slewing bearings feature two rows of cylindrical rollers, which can manage very high loads and moments. The dual-row design enhances the bearing’s load capacity and durability, making it suitable for the most demanding applications.

- Characteristics: These bearings provide superior strength and can handle heavy-duty loads with ease. They are often used in applications that require long service life and high reliability, such as construction machinery and large cranes.

- Applications: Double-row roller slewing bearings are used in heavy-duty applications like large excavators, mining equipment, and large offshore cranes, where maximum load capacity and robustness are crucial.

5. Three-Row Roller Slewing Bearings

Three-row roller slewing bearings are the most robust type of slewing bearings, with three distinct rows of rollers separated by raceways. This design allows each row to bear different loads (axial, radial, and moment loads) independently.

- Characteristics: These bearings offer the highest load capacity of all slewing bearings, making them suitable for extreme load applications. The three-row design also provides excellent rigidity and stability, ensuring smooth operation under heavy loads.

- Applications: Three-row roller slewing bearings are ideal for applications with extreme load requirements, such as heavy-duty cranes, marine cranes, bucket wheel excavators, and large wind turbines.

6. Light Series Slewing Bearings

Light series slewing bearings are designed for applications where weight and space are limited, but high load capacity is not necessarily required. These bearings are typically smaller in size and have a thinner profile.

- Characteristics: Light series slewing bearings are lightweight and easy to install, making them suitable for applications where compactness and simplicity are more important than load-bearing capabilities.

- Applications: They are used in applications like satellite dishes, radar antennas, and small rotary tables, where compact design and easy installation are key.

Choosing the Right Slewing Bearing

Selecting the right slewing bearing for an application involves considering several factors:

- Load Requirements: Understanding the type and magnitude of loads (axial, radial, and moment) that the bearing will encounter is crucial. This will determine whether a single-row, double-row, or triple-row bearing is appropriate.

- Space Constraints: The physical space available for the bearing will influence the choice. Compact bearings like single-row or cross-roller bearings are ideal for tight spaces.

- Rotational Speed: The required speed of rotation can also dictate the choice. Ball bearings generally offer lower friction and higher speeds, making them suitable for applications where speed is a priority.

- Environmental Conditions: The operating environment, including exposure to contaminants, moisture, or extreme temperatures, can affect bearing performance. Sealed bearings with appropriate lubrication are essential for harsh environments.

Conclusion

Slewing bearings are versatile components that play a critical role in a wide range of applications, from light-duty equipment to heavy machinery. By understanding the different types of slewing bearings and their unique characteristics, engineers and designers can select the most suitable bearing for their specific needs, ensuring optimal performance and longevity of their equipment.