Expert Slewing Ring Repair: Your Guide to Remanufacture and Replacement

2025-05-24

Slewing rings are the unsung heroes in a vast array of heavy machinery, enabling critical rotational movement. When these vital components face wear or damage, understanding your options for repair or remanufacture can save significant costs and minimize downtime. This article delves into the intricacies of slewing ring repair, exploring the repair process, when to opt for it over replacement, and how an expert approach can breathe new life into your slewing bearing. If you’re looking to extend the lifespan of your equipment and make economically sound decisions, read on to discover how professional slewing ring repair services can be a game-changer.

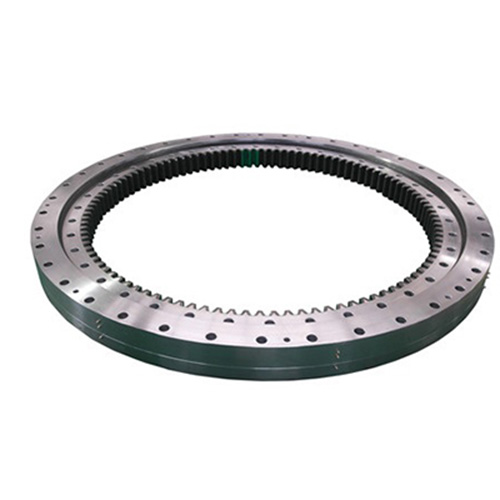

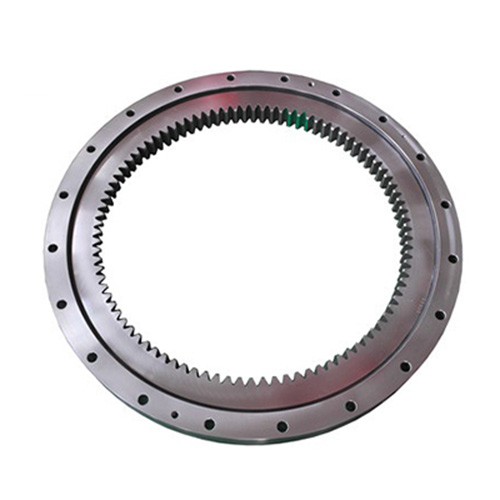

1. What Exactly is a Slewing Ring and Why is its Repair So Crucial?

A slewing ring, often called a slewing bearing or turntable bearing, is a large-diameter bearing that can simultaneously accommodate axial, radial, and tilting moment loads. Think of it as a rotational joint that allows heavy structures to turn smoothly and safely. You’ll find them in everything from construction cranes and excavators to wind turbines, medical scanners, and even bottling plants. The ability of these bearings to handle immense load and facilitate precise movement is fundamental to the operation of the equipment they are part of.

The crucial nature of slewing ring repair stems from several factors. Firstly, a failing slewing ring can bring entire operations to a standstill, leading to costly downtime. Imagine a large crane on a construction site unable to swivel – the project grinds to a halt. Secondly, the cost of a new slewing ring bearing, especially for large or custom applications, can be substantial. Repair or remanufacture, when feasible, offers a significantly more economical alternative. Finally, a compromised slewing bearing can pose serious safety risks. If it fails catastrophically, it could lead to equipment collapse, property damage, and, most importantly, endanger personnel. Therefore, timely and expert repair is not just about cost savings; it’s about maintaining operational integrity and safety.

As a factory specializing in slewing ring design and manufacture, we at Xinda Slewing Bearing understand the intricate engineering that goes into these components. We’ve seen firsthand how proactive maintenance and skilled repair can extend the service life of these critical parts, ensuring they continue to perform reliably.

2. When Should You Consider Slewing Ring Repair Over a New Replacement?

Deciding between repairing a slewing ring and purchasing a new replacement involves careful consideration of several factors. For someone like Mark Thompson, a company owner and procurement officer who values both quality and competitive pricing, this decision is paramount. The primary driver is often cost. Generally, if the repair cost is less than 50-60% of the price of a new bearing, repair is a very attractive option. However, cost isn’t the only factor.

The extent of the damage is a critical determinant. Minor issues like early-stage raceway spalling, seal damage, or slight gear wear can often be effectively addressed through repair or remanufacture. However, if the slewing ring has suffered catastrophic failure, such as a major crack through the ring structure or extensive, deep raceway damage, it might be beyond repair. Lead time is another consideration. Manufacturing a new, large-diameter slewing ring bearing can take weeks or even months, especially for custom designs. A repair process, on the other hand, can often be completed much faster, significantly reducing downtime. This is particularly important for industries like mining or construction where every hour of inoperable machinery translates to lost revenue.

Furthermore, the availability of a new replacement plays a role. For older or highly specialized equipment, finding an exact new bearing might be difficult or impossible. In such cases, remanufacture becomes an invaluable solution, restoring the existing component to its original specification or even enhancing it. We often advise customers to get a thorough inspection and a quote for both options to make an informed decision.

3. The Initial Inspection: What Does a Thorough Slewing Ring Assessment Involve?

The foundation of any successful slewing ring repair or remanufacturing process is a comprehensive inspection. This isn’t just a quick look-over; it’s a detailed diagnostic procedure designed to identify all existing and potential issues. When a slewing ring arrives at our facility, the first step is a visual inspection of the slewing ring surfaces for obvious signs of damage, such as cracks, corrosion, or gear tooth wear. We also check the seals for integrity.

Following the visual check, meticulous dimensional measurements are taken. This includes checking the diameter of the inner and outer rings, raceway profiles, and gear geometry if present. These measurements are compared against the original manufacturing specifications or, if unavailable, against standard tolerances for that type of slewing bearing. Clearance measurements are also critical, as excessive play can indicate significant internal wear.

The most crucial part of the inspection often involves non-destructive testing (NDT) techniques. Magnetic particle inspection is commonly used to detect cracks or defects on the surface and near-surface of ferromagnetic materials. For deeper flaws or in non-magnetic materials, ultrasonic testing might be employed. These NDT methods are vital for uncovering hidden damage that could compromise the repaired slewing ring if left unaddressed. We also analyze lubricant samples, if available, for wear debris, which can provide clues about the internal condition of the ring before disassembly. This thorough inspection ensures that we have a complete picture of the bearing’s condition, allowing us to determine the feasibility of repair and plan the most effective repair techniques.

4. Unveiling the Slewing Ring Repair Process: A Step-by-Step Guide

Once a slewing ring is deemed repairable after the initial inspection, the actual repair process begins. This is a methodical sequence of operations designed to restore the bearing to a like-new condition. As a factory, we have a well-defined workflow for this.

- Disassembly and Cleaning: The slewing ring is carefully disassembled. All components, including rolling elements (balls or rollers), spacers or cages, seals, and rings, are meticulously cleaned to remove old grease, debris, and contaminants. This step is crucial for accurate assessment of individual parts.

- Detailed Component Inspection: Each component is then subjected to another round of detailed inspection. Raceways are examined for pitting, spalling, and wear. Rolling elements are checked for flatness, roundness, and surface damage. Gear teeth (if applicable) are inspected for wear patterns, pitting, or fractures.

- Repair and Reconditioning: This is where the core repair techniques are applied.

- Raceway Grinding: If raceways have minor to moderate wear, they can often be re-ground to restore their original profile and surface finish. This requires specialized precision grinding equipment.

- Gear Repair: Damaged gear teeth might be repaired through weld buildup followed by re-machining to the correct profile. In some cases, individual gear segments can be replaced.

- Crack Repair: Minor cracks in non-critical areas might be repaired by weld techniques, but this is done with extreme caution and depends heavily on the crack location and severity.

- Replacement of Worn Parts: Rolling elements, seals, and spacers are often replaced with new ones, as these are typically wear items and their replacement is cost-effective. You can explore options like our I.1166.20.00.B Ball Slewing Bearing for new components if needed.

- Reassembly: The slewing ring is carefully reassembled with new or reconditioned components. Proper lubrication is applied according to the application requirements.

- Final Testing and Quality Control: The reassembled ring undergoes rigorous testing to ensure it meets performance specifications. This typically includes rotational torque testing, clearance checks, and sometimes load testing depending on the application and customer requirements.

This step-by-step approach ensures that every aspect of the slewing bearing is addressed, leading to a reliable and high-quality repair.

5. What are the Advanced Repair Techniques Used by Experts?

While basic repair steps like cleaning and replacing seals are common, expert slewing ring repair services employ more advanced repair techniques to tackle complex damage and enhance the longevity of the repaired slewing ring. These methods often require specialized knowledge, engineering expertise, and sophisticated equipment.

One such technique is thermal spraying. This process involves melting a material (metal, ceramic, or composite) and spraying it onto the worn surface of the slewing ring raceway or gear. This can be used to build up worn areas, improve wear resistance, or enhance corrosion resistance. After spraying, the surface is typically ground or machined to the required dimension and finish. Another advanced technique is precision raceway grinding. Unlike simple polishing, this involves using CNC grinders to precisely restore the raceway geometry to optimize load distribution and rotational smoothness. This is particularly critical for high-precision applications.

For gear repair, specialized weld procedures using compatible materials and controlled pre-heating and post-weld heat treatment are essential to maintain the gear’s strength and hardness. In some cases, if a section of the gear is severely damaged, expert shops might cut out the damaged section and weld in a new, precisely machined segment. Furthermore, advanced non-destructive testing (NDT) methods like phased array ultrasonic testing can provide more detailed insights into the internal structure of the ring, helping to detect cracks or defects that might be missed by standard magnetic particle inspection to detect cracks. These advanced repair techniques are what differentiate a simple patch-up from a true remanufacture that brings the slewing bearing close to its original performance capabilities.

6. Beyond Simple Fixes: Understanding Slewing Bearing Remanufacture

The term "remanufacture" or "bearing remanufacturing process" goes a step beyond standard slewing ring repair. While repair might focus on addressing specific, localized damage, remanufacture aims to restore the entire slewing bearing to its original specification or even improve upon it. This is a comprehensive process, almost like building a new bearing using some of the original, reconditioned core components. We consider our services at Xinda Slewing Bearing as a High Quality Slewing Ring Bearings Supplier that also excels in these detailed remanufacturing processes.

The remanufacturing process includes all the steps of a detailed repair, but often with a greater emphasis on replacing all wear components (like rolling elements and seals) regardless of their apparent condition, and performing more extensive re-machining of raceways and gear profiles. For instance, if raceways are significantly worn, they might be ground deeper, and then oversized rolling elements might be used to maintain the correct operating clearance. If the original material had limitations, remanufacture might involve applying advanced surface treatments like plating or specialized coatings to enhance wear resistance or corrosion resistance, thereby improving upon the original design.

A key advantage of remanufacture is that it can often provide a "like-new" slewing ring at a fraction of the cost of a new one, with a warranty that reflects the quality of the work. This is especially valuable for large, expensive bearings or those that are no longer in production. The bearing remanufacturing process for components like Kaydon bearings or other specialized turntable bearings can offer substantial cost savings and quicker turnaround compared to sourcing a new replacement. It’s a sustainable option that conserves resources by reusing the main structural components of the ring.

7. How Does Expert Maintenance Prolong the Life of Your Slewing Ring?

While repair and remanufacture are excellent options for addressing existing damage, proactive maintenance is key to maximizing the operational life of any slewing ring and minimizing the need for extensive repair slewing work. As an operator or procurement officer like Mark, understanding and implementing proper maintenance practices can lead to significant long-term savings and improved reliability.

Regular lubrication is perhaps the single most important preventive maintenance task. The correct type and amount of grease, applied at the recommended intervals, reduce friction, prevent corrosion, and help dissipate heat. It’s crucial to follow the equipment manufacturer’s guidelines for lubrication. Another vital aspect is routinely checking bolt torque. The bolts securing the slewing ring to its mounting structures must be kept at the correct tension. Loose bolts can lead to uneven load distribution, excessive stress on the ring, and premature failure. Regular inspection for signs of wear, such as unusual noises, increased rotational resistance, or excessive clearance, can help catch problems early before they escalate into major damage.

Seal integrity is also paramount. Seals protect the internal components of the slewing bearing from contaminants like dirt, dust, and moisture, which can drastically shorten its life. Damaged seals should be replaced promptly. Finally, monitoring the operation of the machinery for any unusual vibrations or movements can indicate developing issues with the slewing ring. Implementing a robust preventive maintenance schedule, including these checks, can significantly extend the life of your equipment and reduce the likelihood of unexpected failures and costly emergency repairs. For complex systems, consulting with a slewing ring bearing repair expert for maintenance advice is always a good idea.

8. Critical Testing Post-Repair: Ensuring Your Slewing Bearing is Ready for Duty?

Once the repair or remanufacturing process of a slewing ring is complete, rigorous testing is essential to ensure it meets the required performance standards and is safe for operation. This isn’t a step to be skipped or rushed, as the reliability of the repaired slewing ring hinges on it. As a manufacturer, we integrate stringent quality control and testing at various stages, especially post-assembly.

The most common tests include:

- Rotational Torque Test: This measures the effort required to rotate the slewing ring. An abnormally high or inconsistent torque can indicate issues with internal clearance, lubrication, or component alignment.

- Clearance Measurement: The axial and radial clearance (or "play") within the bearing is re-checked to ensure it falls within the specified tolerances for the particular application. Excessive clearance can lead to poor load distribution and instability, while too little can cause binding and overheating.

- Runout Test: This measures the deviation of the ring surfaces as it rotates, ensuring that the repair has maintained the necessary geometric accuracy.

- Contact Pattern Check (for geared rings): For slewing rings with integral gears, the contact pattern between the gear teeth and the mating pinion is often checked to ensure proper meshing and load distribution. This might involve applying a marking compound and running the gear.

- Non-Destructive Testing (NDT): In some cases, especially after weld repairs or for critical applications, NDT methods like magnetic particle inspection to detect any surface-breaking flaws might be performed again on the reassembled ring.

For particularly demanding applications, such as those in mining excavators or large cranes, more comprehensive testing, potentially including simulated load capacity tests, might be required. A detailed test report is typically provided with the repaired slewing ring, giving the customer confidence in the quality of the repair and the readiness of the component for re-installation.

9. Choosing a Partner: What to Look for in a Slewing Ring Repair Expert?

Selecting the right service provider for your slewing ring repair or remanufacture is as critical as the repair itself. For Mark Thompson, who seeks quality and reliability, this choice significantly impacts his business’s efficiency and profitability. An expert in slewing ring repair will possess a combination of experience, technical capability, and a commitment to quality.

Key factors to consider include:

- Experience and Specialization: Look for a company that specializes in slewing bearing repair and remanufacture, not just general machining. Ask about their experience with your specific type of slewing ring and application. For example, we have extensive experience with various types, including E1144.30.12.D.3-RV Cylindrical roller bearing.

- Technical Capabilities and Equipment: Do they have the necessary precision grinding machines, welding facilities, NDT equipment, and testing rigs? Can they handle the diameter and weight of your ring?

- Engineering Support: A good repair shop will have engineering staff who can analyze failures, recommend appropriate repair techniques, and potentially suggest improvements to prevent future issues.

- Quality Control Processes: Inquire about their quality assurance procedures, from initial inspection to final testing. Do they follow recognized industry standards?

- Warranty: A reputable repair service will stand behind their work with a meaningful warranty on the repaired slewing ring.

- Turnaround Time and Communication: While quality is paramount, realistic turnaround times are important. Good communication throughout the repair process is also a sign of a professional operator.

- References and Case Studies: Don’t hesitate to ask for references or case studies of similar repairs they have successfully completed.

Choosing a partner with a proven track record, like us at Xinda Slewing Bearing, ensures that your slewing ring is in capable hands and that the repair will be performed to the highest standards, extending the life of your equipment.

10. The Bottom Line: Cost-Effectiveness and Sustainability of Slewing Ring Repair

For any business, the financial implications of maintenance decisions are paramount. Slewing ring repair and remanufacture offer compelling cost savings compared to purchasing a new replacement, often ranging from 40% to 70% less than the cost of a new bearing. This is a significant financial advantage, especially for large or specialized slewing rings where the initial investment is high. Reduced downtime is another major economic benefit. A faster repair process means your machinery is back in operation sooner, minimizing lost production and revenue. This is a crucial factor for mine operators and construction companies who rely heavily on their equipment.

Beyond the immediate cost savings, slewing ring repair is also a more sustainable option. The remanufacturing process reuses the main structural components of the ring, conserving raw materials and the energy required for manufacturing a completely new bearing. This reduces the environmental footprint associated with your equipment‘s maintenance. By extending the service life of existing components, we collectively contribute to a more circular economy.

The decision to repair also positively impacts inventory management. Instead of stocking numerous expensive new replacement bearings, companies can rely on timely repair services. While not every slewing ring is a candidate for repair – some are genuinely beyond repair – a thorough inspection by an expert can determine if it’s an economically viable and technically sound option. The combination of direct cost savings, reduced downtime, and environmental benefits makes slewing ring repair and remanufacture a smart choice for many applications, from excavator arms to wind turbine nacelles.

Key Takeaways to Remember:

- Crucial Component: Slewing rings are vital for heavy machinery, and their failure can lead to significant downtime and costs.

- Repair vs. Replacement: Consider repair if costs are 50-60% less than a new bearing, damage is manageable, and lead times for a new replacement are long.

- Thorough Inspection is Key: A detailed initial inspection, including non-destructive testing like magnetic particle inspection, is essential to assess damage accurately.

- Systematic Repair Process: Expert repair involves disassembly, cleaning, detailed component inspection, specific repair techniques (grinding, welding), reassembly, and lubrication.

- Remanufacturing for Like-New Performance: Remanufacture aims to restore the slewing bearing to its original specifications, often replacing all wear components and potentially enhancing its design.

- Maintenance Matters: Regular lubrication, bolt torque checks, and seal inspections can significantly extend the life of a slewing ring.

- Post-Repair Testing is Non-Negotiable: Torque tests, clearance checks, and other functional tests ensure the repaired slewing ring is fit for duty.

- Choose Experts Wisely: Look for specialized experience, technical capabilities, robust quality control, and good warranties when selecting a repair service like Xinda Slewing Bearing.

- Cost-Effective & Sustainable: Repair offers substantial cost savings, reduces downtime, and is an environmentally friendlier option than always opting for a new bearing.