How Does a Roller Slewing Ring Work?

2024-08-13

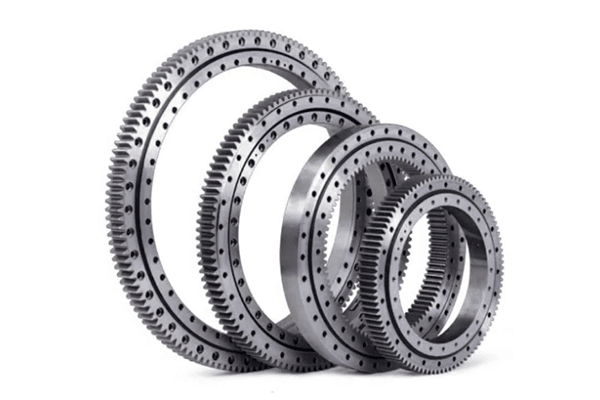

In various industries, from construction to manufacturing, roller slewing rings play a crucial role in enabling heavy machinery and equipment to rotate smoothly and efficiently. These essential components are found in cranes, excavators, wind turbines, and other large machines that require precise and reliable rotational motion. But how exactly does a roller slewing ring work?

Understanding the Basics of a Slewing Ring

A slewing ring, also known as a slewing bearing, is a type of large-scale bearing designed to handle axial, radial, and moment loads simultaneously. Unlike traditional bearings, which typically manage either radial or axial loads, slewing rings can support loads in all directions, making them ideal for applications where rotation and stability are critical.

Roller slewing rings are a specific type of slewing bearing that uses cylindrical rollers instead of balls as rolling elements. These rollers allow the bearing to carry heavier loads and provide higher stiffness, which is essential in heavy-duty applications.

Components of a Roller Slewing Ring

A roller slewing ring typically consists of the following components:

- Inner and Outer Rings: The inner and outer rings are the main structural elements of the slewing ring. They are usually made of hardened steel to withstand heavy loads and harsh working conditions. The rings contain raceways where the rollers move, ensuring smooth rotation.

- Rollers: Cylindrical rollers are placed between the inner and outer rings. These rollers are positioned in a circular arrangement and can rotate independently, allowing the slewing ring to handle high loads and distribute them evenly across the bearing.

- Spacer Cages: Spacer cages are used to maintain the correct spacing between the rollers, preventing them from coming into direct contact with each other. This spacing reduces friction and wear, enhancing the bearing’s lifespan and performance.

- Seals: Seals are essential for protecting the internal components of the slewing ring from contaminants such as dust, dirt, and moisture. Proper sealing ensures that the bearing operates smoothly and maintains its performance over time.

How Roller Slewing Rings Work

The operation of a roller slewing ring is based on the movement of the rollers between the inner and outer rings. Here’s how it works:

- Load Distribution: When a load is applied to the slewing ring, it is distributed across the rollers. The cylindrical shape of the rollers allows them to carry high loads with minimal deformation, providing stability to the rotating structure.

- Rolling Motion: As the slewing ring rotates, the rollers move along the raceways of the inner and outer rings. The rollers roll smoothly due to the precision-machined raceways, ensuring minimal friction and efficient load transfer.

- Handling Multidirectional Loads: Roller slewing rings are designed to handle axial loads (forces parallel to the axis of rotation), radial loads (forces perpendicular to the axis of rotation), and moment loads (torques that cause rotation around the axis). The ability to manage these multidirectional loads simultaneously is what makes slewing rings indispensable in heavy-duty applications.

- Controlled Rotation: The smooth rolling motion of the rollers allows for controlled and precise rotation of the attached equipment or structure. This controlled rotation is crucial in applications such as cranes, where precise positioning is necessary.

Applications of Roller Slewing Rings

Roller slewing rings are used in various industries and applications, including:

- Cranes and Lifting Equipment: Roller slewing rings enable the smooth rotation of cranes, allowing them to lift and position heavy loads with precision.

- Excavators and Construction Machinery: In construction equipment, slewing rings allow for the 360-degree rotation of the machinery, enhancing its maneuverability and functionality.

- Wind Turbines: In wind turbines, slewing rings are used to rotate the blades and the nacelle, allowing the turbine to capture wind from any direction.

- Manufacturing and Robotics: Slewing rings are also used in manufacturing processes and robotic arms, where precise and controlled movement is required.

Conclusion

Roller slewing rings are vital components in a wide range of heavy-duty applications, providing the necessary rotation, stability, and load-bearing capacity needed for large machinery and equipment. By distributing loads across cylindrical rollers and allowing for smooth, controlled movement, these bearings ensure the efficient operation of cranes, excavators, wind turbines, and more. Understanding how a roller slewing ring works highlights its importance in enabling the functionality and reliability of modern industrial equipment.