Innovative Technologies for the Slewing Ring Drive Industry

2024-08-05

The slewing ring drive industry is experiencing rapid advancements, driven by the need for more efficient, compact, and versatile components. These innovations are reshaping how slewing rings are utilized across various sectors, from robotics to renewable energy. This article explores some of the most cutting-edge technologies emerging in the slewing ring drive industry, highlighting their impact and potential.

Compact and Customizable Solutions

One of the most notable advancements in the industry is the development of more compact and customizable slewing ring bearings. Companies like Igus have introduced slewing ring bearings, such as the PRT-04, which are significantly lighter and smaller than their predecessors. The PRT-04 is 60% lighter and 50% smaller than the PRT-01, making it ideal for applications where space and weight are critical considerations. Additionally, these bearings can be customized through 3D printing, allowing for tailored solutions that meet specific industrial requirements.

Advanced Materials for Enhanced Performance

The use of advanced materials is another significant innovation in slewing ring drive technology. Manufacturers are now utilizing high-performance plastics and composites to produce slewing rings that are not only lightweight but also extremely durable. These materials offer low friction, self-lubricating properties, and high resistance to wear and environmental factors such as dust, dirt, and moisture. For instance, igus’s line of self-lubricating, high-performance plastics ensures that their bearings can operate smoothly in challenging conditions, extending the lifespan and reliability of the components.

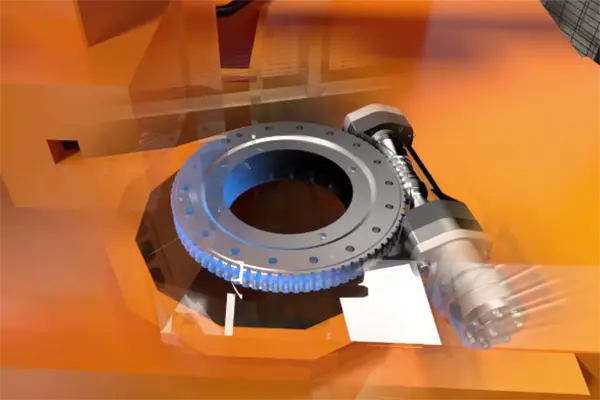

Integration with Automation and Robotics

The integration of slewing ring drives with automation and robotics systems is revolutionizing the industry. The SE series from FDON GROUP is a prime example of how slewing rings are being engineered to meet the demands of high-precision and complex motion control. These models are designed to provide accurate rotation control, which is essential for robotic arms, automated manufacturing lines, and other high-tech applications. The ability to precisely control rotational movements enhances the efficiency and effectiveness of automated systems, driving productivity and innovation.

Renewable Energy Applications

Slewing ring drives are playing a crucial role in the renewable energy sector, particularly in wind turbines and solar tracking systems. The advanced design of modern slewing rings allows for precise positioning and movement control, which is essential for optimizing the capture of solar and wind energy. By facilitating the accurate alignment of solar panels and the efficient rotation of wind turbine blades, slewing rings contribute to maximizing energy output and improving the overall efficiency of renewable energy systems.

Smart Technology and Monitoring

The incorporation of smart technology into slewing ring drives is another emerging trend. By integrating sensors and monitoring systems, manufacturers can provide real-time data on the performance and condition of the bearings. This data can be used for predictive maintenance, allowing for timely interventions before failures occur. Smart slewing rings can detect issues such as excessive wear, misalignment, or lubrication problems, enabling operators to address these issues proactively. This approach not only extends the lifespan of the components but also reduces downtime and maintenance costs.

Future Prospects

The future of the slewing ring drive industry looks promising, with continuous advancements in materials, design, and integration. As technology evolves, we can expect to see even more innovative solutions that enhance the performance, reliability, and versatility of slewing rings. The ongoing development of smart technologies and the increasing demand for lightweight, efficient components will drive further innovation, ensuring that the slewing ring drive industry remains at the forefront of mechanical engineering and industrial automation.

Conclusion

Innovative technologies are transforming the slewing ring drive industry, offering new possibilities and applications across various sectors. From compact and customizable solutions to advanced materials and smart monitoring systems, these advancements are enhancing the performance and efficiency of slewing rings. As the industry continues to evolve, these technologies will play a pivotal role in meeting the growing demands of modern engineering and industrial automation, driving progress and innovation in the years to come.