Mastering Crane Slewing Bearings: The Ultimate Guide to Crane Slew Ring Selection and Performance

2025-04-15

Crane slewing bearings, often called slew rings or turntable bearings, are the unsung heroes of heavy lifting equipment. They are the critical component that allows the massive upper structure of a crane to rotate smoothly and safely relative to its undercarriage. Understanding the nuances of these powerful bearings is crucial for anyone involved in the design, procurement, or operation of cranes, excavators, and similar machinery. This article delves deep into the world of crane slewing bearings, exploring their types, selection criteria, maintenance needs, and how to source high-quality components, ensuring your equipment performs reliably and efficiently. Whether you’re a seasoned procurement officer like Mark Thompson, seeking cost-effective yet high-quality bearings, or an engineer specifying components for a new crane design, this guide provides valuable insights from a factory perspective, helping you navigate the complexities of slewing bearing technology.

What Exactly is a Crane Slewing Bearing?

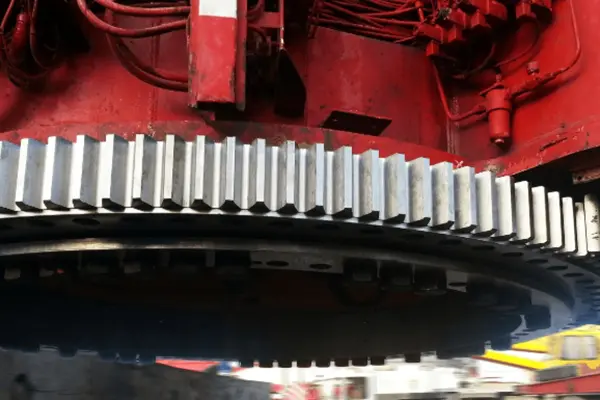

At its core, a slewing bearing is a large-diameter rolling-element bearing designed to handle complex load combinations – simultaneously supporting axial, radial, and tilting moment loads. Think of it as a specialized turntable bearing. For a crane, this bearing forms the rotating interface between the machine’s upper structure (the boom, cab, counterweight) and the lower chassis or pedestal. This rotational movement capability is fundamental to a crane‘s function, allowing it to lift and position heavy loads across a wide operational arc without repositioning the entire machine.

The typical construction involves two concentric rings, one fixed and one rotating, containing rolling elements (balls or rollers) separated by spacers within precisely engineered raceways. Often, one of the rings incorporates gear teeth (either internal or external) to mesh with a drive pinion, enabling powered rotation. The slewing bearing essentially acts as a large, robust joint, critical for the smooth and controlled rotate function essential in crane operations. Its design integrates mounting holes for secure attachment to the mating structures. The complexity lies in designing a bearing that can withstand immense forces while maintaining smooth rotation and precision, a challenge we specialize in at our slewing bearing factory. We produce slewing bearings for a vast array of applications, including excavator crane aerial work platform machinery.

Why is the Slewing Bearing So Critical for Crane Operations?

The slewing bearing is arguably one of the most vital components in any crane. Its primary role is to facilitate the smooth, controlled rotation of the crane’s superstructure while bearing the full brunt of operational loads. These loads aren’t simple; they include the weight of the lifted load, the boom, the counterweight, and dynamic forces generated during lifting and swinging. The bearing must handle significant axial forces (vertical loads), radial forces (horizontal loads), and powerful tilting moments that try to overturn the upper structure. A failure in the crane slewing bearing isn’t just an inconvenience; it can be catastrophic, leading to equipment collapse, property damage, injuries, or worse.

Furthermore, the precision of the slewing bearing directly impacts the crane‘s operational accuracy. Precise positioning of loads requires a bearing with minimal play and smooth rotational movement. Any binding, excessive clearance, or uneven rotation in the slew ring compromises the operator’s control and the overall safety and efficiency of the crane. Therefore, selecting a high-quality, correctly specified crane slewing bearing and ensuring its proper installation and maintenance are paramount. It’s the linchpin connecting the lifting power to the necessary maneuverability, making it indispensable for effective crane functionality. The integrity of this single bearing underpins the entire operational safety envelope of the crane.

What are the Main Types of Slewing Bearings Used in Cranes?

Cranes utilize various types of slewing bearings, chosen based on the specific load requirements, size constraints, and operational demands of the machine. Understanding these types is key to selecting the appropriate bearing. Here are the most common ones:

-

Single Row Four Point Contact Ball Slewing Bearing: This is perhaps the most widely used bearing type for light to medium-duty cranes and excavator applications. It features a single row of balls making four points of contact within specially designed raceways, allowing it to handle axial, radial, and moment loads simultaneously. It’s relatively compact and cost-effective. We offer many variations, like the I.1166.20.00.B Ball Slewing Bearing. The four point contact ball slewing design is versatile. A point contact ball slewing bearing like this provides a good balance of performance and economy.

-

Single Row Cross Roller Slewing Bearing: This bearing uses cylindrical rollers arranged in a crisscross pattern, with each roller oriented perpendicular to the adjacent one. This configuration allows a single row bearing to handle high radial, axial, and moment loads in all directions. They offer higher rigidity and load capacity compared to single row ball slewing bearing designs of similar dimensions, often found in applications requiring greater precision. We manufacture high precison cross roller slewing bearings, including precison cross roller slewing bearing models suitable for demanding tasks.

-

Double Row Ball Slewing Bearing: As the name suggests, this bearing features two rows of balls. Typically, one row handles the primary axial and moment loads, while the second enhances radial capacity or moment resistance. A double row ball slewing bearing offers significantly higher load capacity than a single row ball slewing bearing of comparable size, making it suitable for medium to heavy-duty cranes. Check out our precision models like the 011.20.1220.000.11.1504 Precision double-row ball slewing ring.

-

Three Row Roller Slewing Bearing: This is the heavyweight champion among slewing bearings. It typically utilizes three independent rows of cylindrical rollers. One row takes the primary axial load, another handles the opposing axial load and tilting moment, and the third manages the radial load. This segregation of load paths allows the three row roller slewing bearing to handle extremely heavy loads and significant tilting moments, making it the choice for large construction cranes, offshore cranes, and heavy-duty excavator models. The bearing slewing ring bearing design provides maximum capacity.

Each bearing type, from the single row ball slewing bearing double row ball slewing bearing three row roller slewing bearing slewing ring bearing family, has its specific strengths, and the choice depends heavily on the engineering analysis of the crane‘s operational parameters. We produce the full spectrum, including light slewing bearing high precison cross roller slewing bearing excavator slew bearing crane slewing bearing customized slewing bearing worm gear slew drive options.

How Do I Choose the Right Slewing Bearing for My Crane Application?

Selecting the correct slewing bearing for a crane is a critical engineering decision that directly impacts safety, performance, and lifespan. It’s not just about picking a bearing that fits; several factors must be carefully evaluated:

-

Load Spectrum Analysis: This is the most crucial step. You need to determine the magnitude and nature of all loads the bearing will experience:

- Axial Load: The total vertical force (weight of superstructure, lifted load, etc.).

- Radial Load: Horizontal forces (wind, side loading, etc.).

- Tilting Moment Load: The overturning force generated by the load’s offset from the bearing centerline.

- Dynamic Loads: Forces generated during acceleration, deceleration, and swinging.

A comprehensive analysis considering all operational scenarios is required to calculate the maximum resultant loads and moments.

-

Duty Cycle and Rotational Speed: How often will the crane slew ring rotate, and at what speed? Continuous rotation or high speeds might necessitate specific lubrication systems or bearing designs (e.g., roller bearings generally handle higher speeds better than ball bearings of the same size).

-

Size and Space Constraints: The physical dimensions available for mounting the slewing bearing (inner diameter, outer diameter, height) often dictate the feasible bearing types and sizes.

-

Gear Requirements: Does the application require powered rotation? If so, will it need an internal gear slewing bearing, an external gear slewing bearing, or a slewing bearing without gear flange slewing bearing design? The gear module, pitch diameter, and quality must match the drive pinion. We offer bearing with external gear slewing options and gear slewing bearing with internal configurations.

-

Operating Environment: Will the crane operate in corrosive environments (marine, chemical plants), extreme temperatures, or dusty conditions? This influences the choice of materials, coatings, and sealing arrangements needed to protect against environmental factors.

-

Required Precision and Rigidity: Applications like medical scanners or robotic arms require much higher precision and rigidity than a standard construction crane. This might favor high precison cross roller slewing bearings.

-

Compliance and Standards: Ensure the slewing bearing complies with relevant industry standards (e.g., ISO, AGMA for gears).

As a manufacturer, we often assist customers like Mark Thompson by reviewing their application data and recommending the most suitable bearing. Providing detailed operational parameters allows us to leverage our expertise to ensure the selected slewing bearing, whether it’s a single row ball slewing bearing or a complex three row roller slewing bearing, meets or exceeds the requirements, balancing performance with cost-effectiveness.

Internal Gear, External Gear, or Non-Geared: Which Slewing Ring is Best?

The choice between a slewing bearing with internal gear, an external gear slewing bearing, or a non-geared slewing bearing depends entirely on the crane‘s design and drive mechanism. Each configuration has distinct advantages and considerations:

-

External Gear Slewing Bearing:

- Description: The gear teeth are machined on the outer diameter of the stationary or rotating ring. The drive pinion engages these teeth from the outside.

- Pros: Pinion mounting is generally simpler and more accessible for maintenance and inspection. Can sometimes allow for a more compact overall drive system height.

- Cons: The gear and pinion are exposed, potentially requiring additional guarding for protection against damage and environmental contaminants. May require slightly larger overall machine footprint compared to internal gear designs for the same bearing size. The slewing ring bearing with external gear is common in many crane and excavator applications. We offer robust ring bearing with external gear options.

-

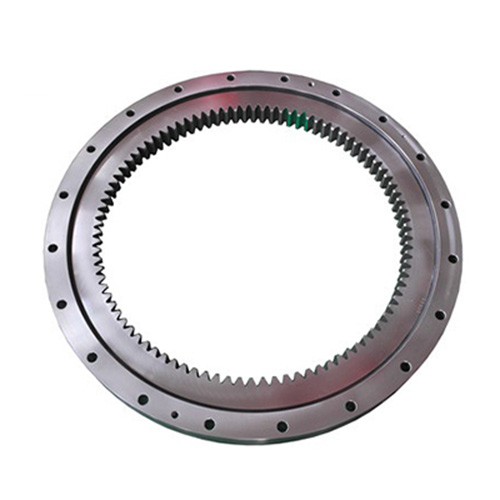

Slewing Bearing with Internal Gear:

- Description: The gear teeth are cut into the inner diameter of one of the rings. The pinion engages from within the bearing‘s bore.

- Pros: Offers inherent protection for the gear teeth and pinion meshing area from external impacts and debris. Can allow for a more compact machine design radially. Often preferred for aesthetic reasons or where external obstructions are a concern.

- Cons: Pinion mounting and access for maintenance can be more complex, often requiring specific designs for installation and inspection. May require careful consideration of the inner ring structure to accommodate the drive system. The internal gear slewing bearing without gear flange slewing bearing light slewing bearing configuration offers design flexibility.

-

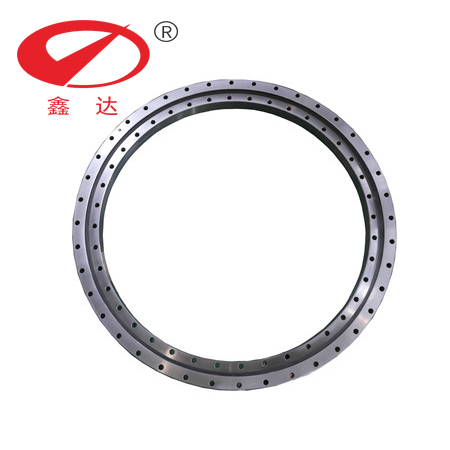

Non-Geared Slewing Bearing:

- Description: Neither ring has integrated gear teeth. Rotation is typically achieved through other means, such as a chain drive, hydraulic motor acting directly on the structure, or manual positioning.

- Pros: Simpler bearing design, potentially lower cost for the bearing itself. Suitable for applications where powered slewing isn’t required or is provided externally.

- Cons: Requires a separate, potentially more complex, external drive mechanism if powered rotation is needed.

The "best" choice isn’t universal; it’s application-specific. For most crane applications requiring powered slewing, the decision between internal and external gears comes down to design integration, space constraints, environmental protection needs, and maintenance accessibility preferences. As manufacturers, we produce all three types – bearing with internal gear slewing, bearing with external gear slewing, and non-geared slewing bearings – offering standard and customized slewing bearing solutions to fit diverse crane designs.

How Can Quality and Load Capacity Be Verified in a Slewing Bearing?

For procurement professionals like Mark Thompson, verifying the quality and load capacity of a slewing bearing sourced from overseas is a paramount concern. Reputable manufacturers employ rigorous quality control processes and provide documentation to assure customers. Here’s how verification typically works:

-

Material Certifications: Insist on mill certificates for the steel used in the bearing rings and rolling elements. These documents verify the material composition, heat treatment, and mechanical properties (like hardness and strength), ensuring they meet the design specifications crucial for load capacity. We provide full traceability for our raw materials.

-

Dimensional Accuracy Reports: Precision manufacturing is key. Request inspection reports confirming that critical dimensions – diameters, concentricity, flatness, gear geometry (if applicable), and mounting hole patterns – are within the specified tolerances. Accurate dimensions ensure proper fit, load distribution, and smooth operation. Our multiple production lines utilize CNC machining and CMM inspection for high accuracy.

-

Load Capacity Calculations and FEA: The manufacturer should provide detailed load capacity ratings (static and dynamic) based on established engineering principles (e.g., ISO standards). For critical applications or custom designs, Finite Element Analysis (FEA) reports can demonstrate how the bearing will perform under the specified complex loads. We perform FEA to validate our slewing bearing designs.

-

Gear Quality Inspection (if applicable): For geared slewing bearings (internal gear slewing bearing or external gear slewing bearing), gear quality reports (e.g., AGMA or ISO standards) are vital. These check parameters like tooth profile, pitch error, runout, and surface finish, ensuring smooth meshing, low noise, and long gear life.

-

Non-Destructive Testing (NDT): Techniques like Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) can be used to detect subsurface flaws or surface cracks in critical areas like raceways and gear teeth, ensuring the integrity of the bearing components.

-

Factory Audits and Reputation: While challenging from afar, researching the supplier’s reputation, certifications (e.g., ISO 9001), export history (especially to demanding markets like the USA, Europe, Australia), and potentially conducting a third-party factory audit can provide significant assurance about their capabilities and quality systems. Visiting during exhibitions is also a good way to assess suppliers.

Clear communication is vital. Discussing these verification requirements upfront ensures alignment and builds confidence. As a factory specializing in slewing bearings, we understand these concerns and proactively provide comprehensive documentation to support the quality and performance of our bearing products, from a standard single row ball slewing bearing to a heavy-duty three row roller slewing bearing.

What Leads to Common Failures in Crane Slewing Bearings?

Despite being robustly designed, crane slewing bearings can eventually fail due to various factors. Understanding these common failure modes helps in prevention through proper selection, installation, and maintenance:

-

Raceway Wear and Spalling: This is often the ultimate end-of-life failure mode. Repeated stress cycles cause microscopic fatigue cracks below the raceway surface, which eventually propagate, causing material to flake off (spalling). This leads to rough rotation, increased noise, and eventual seizure. Overloading, inadequate lubrication, or contamination can accelerate this process.

-

Contamination: Dirt, debris, water, or process materials entering the bearing can severely damage raceways and rolling elements through abrasion and corrosion. Failed or inadequate seals are the primary culprits. This highlights the importance of effective sealing solutions tailored to the operating environment.

-

Inadequate Lubrication: Too little, too much, or the wrong type of grease can lead to premature failure. Insufficient lubrication causes metal-to-metal contact, high friction, heat, and rapid wear. Over-lubrication can cause excessive heat buildup and churn the grease, degrading its properties. Using grease incompatible with the application (temperature, load, speed) is also detrimental. The bearing needs the right lubricant film.

-

Gear Wear or Damage (Geared Bearings): In slewing bearing with internal gear or external gear slewing bearing designs, improper pinion alignment, incorrect backlash, overloading, or inadequate lubrication can cause excessive wear, pitting, or tooth breakage on the gear teeth.

-

Bolt Failure: The bolts securing the slewing bearing rings to the mating structures are critical. Improper bolt tension (too loose or too tight), incorrect bolt grade, or uneven tightening can lead to bolt fatigue, loosening, or breakage, causing catastrophic failure of the connection. Regular bolt torque checks are essential.

-

False Brinelling: Occurs when the bearing is subjected to vibration while stationary. The rolling elements create indentations in the raceways, leading to noisy and rough rotation when slewing resumes. This is common during transport or when equipment vibrates without rotating.

Preventing these failures hinges on selecting the right bearing for the load, ensuring proper installation (especially mounting flatness and bolt tension), implementing a rigorous lubrication schedule with the correct grease, and protecting the bearing with effective seals. Understanding these potential issues informs better preventative maintenance strategies for every crane slewing bearing.

How Critical is Regular Maintenance for Slewing Bearing Longevity?

Regular maintenance is crucial for maximizing the service life and ensuring the safe, optimal performance of any crane slewing bearing. Neglecting maintenance is a direct path to premature failure, costly downtime, and potential safety hazards. The investment in a maintenance program pales in comparison to the cost of replacing a large slew ring and the associated crane downtime.

Key maintenance activities include:

- Lubrication: This is the single most important maintenance task. Follow the manufacturer’s recommendations regarding the type of grease, the quantity, and the re-lubrication intervals. Ensure grease is purged through the seals to flush out contaminants. Different operating conditions (temperature, load, contamination levels) may require adjustments to the lubrication schedule. Proper lubrication minimizes friction and wear in the raceways and on gear teeth (for geared slewing bearings).

- Seal Inspection: Regularly inspect the seals for damage, wear, or detachment. Effective seals are vital to prevent contamination ingress, a major cause of bearing failure. Replace damaged seals promptly.

- Bolt Torque Checks: Periodically check the tension of the mounting bolts using a calibrated torque wrench, following the manufacturer’s specified procedure and torque values. Loose bolts can lead to excessive play and catastrophic failure, while over-tightened bolts can distort the bearing rings.

- Gear Inspection (Geared Bearings): For slewing bearing with internal gear or external gear slewing bearing types, periodically clean and inspect the gear teeth for wear patterns, pitting, or damage. Ensure proper pinion alignment and backlash. Apply gear lubricant as recommended.

- Operational Checks: Listen for unusual noises (grinding, popping), feel for excessive vibration or heat, and check for increased rotational resistance or "play" during operation. These can be early indicators of developing problems within the crane slewing bearing.

Implementing a consistent maintenance schedule, tailored to the specific crane and its operating environment, is fundamental to achieving the expected longevity and optimal performance from the slewing bearing. It protects the investment and ensures the continued safe operation of valuable equipment like cranes and excavators.

Finding Reliable Slewing Bearing Suppliers: What to Look For?

For buyers like Mark Thompson, navigating the global market to find reliable slewing bearing suppliers, especially from countries like China, requires due diligence. Price is a factor, but quality, reliability, and communication are equally important to avoid costly pain points. Here’s what to look for:

- Manufacturing Expertise and Experience: Look for established factories specializing in slewing bearings, not just general trading companies. Verify their experience, particularly in producing the specific bearing types you need (e.g., single row ball slewing bearing, three row roller slewing bearing, crane slewing bearing). How long have they been exporting to demanding markets like the USA or Europe? This indicates familiarity with international standards and expectations. We, as Allen representing our factory, pride ourselves on years of specialized experience.

- Comprehensive Product Range: A supplier offering a wide range of slewing bearings (different types, sizes, gear configurations like bearing with internal gear slewing or bearing with external gear slewing, light type & flange slewing ring bearings, inch size slewing ring bearings) suggests broad technical capability. This includes related slewing bearings and components like slewing gear. Brands like swbtec slewing bearings might be referenced, but direct factory relationships often provide better value and customization.

- Quality Management Systems: Does the supplier have robust quality certifications like ISO 9001? Do they clearly outline their quality control processes, from raw material inspection to final product testing? Ask about their testing equipment and procedures for verifying load capacity, dimensional accuracy, and material properties.

- Technical Support and Customization: A good supplier should have knowledgeable engineers who can discuss technical requirements, assist with bearing selection, and offer customization if standard products don’t perfectly fit. Can they provide drawings, FEA analysis, and detailed technical specifications?

- Communication and Responsiveness: Efficient communication is vital, especially across time zones and language barriers. Look for suppliers with responsive sales and technical teams who can clearly understand your needs and provide timely updates. This addresses a key pain point often experienced by procurement officers.

- Track Record and References: Ask for references or case studies, particularly for applications similar to yours (e.g., excavator slew bearing crane slewing bearing applications). Positive feedback from other customers in your region or industry is a strong indicator of reliability. Visiting suppliers at exhibitions allows for direct interaction and assessment.

- Transparent Pricing and Lead Times: While seeking competitive pricing, ensure quotes are comprehensive and clearly state what’s included. Realistic lead times are crucial; suppliers should be upfront about production schedules and manage expectations effectively to avoid impacting your production.

Finding a supplier involves balancing cost with these critical factors. A reliable partner understands that providing a quality slewing bearing is just the start; consistent performance, dependable delivery, and strong support are key to a long-term relationship.

What Should Procurement Expect When Working with a Slewing Bearing Manufacturer?

Engaging directly with a slewing bearing manufacturer like us offers several advantages but also requires clear expectations from the procurement side, especially for professionals like Mark Thompson prioritizing efficiency and reliability.

- Direct Communication: Expect direct access to knowledgeable sales and engineering staff. This facilitates clearer technical discussions, faster responses to queries, and better understanding of customization possibilities compared to working through intermediaries. Good communication should proactively address potential issues, like lead time updates.

- Technical Collaboration: Manufacturers should be partners in finding the optimal bearing solution. Expect them to review your application data, ask clarifying questions, recommend suitable bearing types (single row ball slewing bearing, double row ball slewing bearing, three row roller slewing bearing, cross roller slewing bearing single row ball slewing bearing double row ball slewing bearing three row roller slewing bearing slewing ring bearing etc.), and provide supporting technical documentation (drawings, load calculations).

- Quality Assurance Transparency: Expect detailed information on quality control procedures, material sourcing, testing methods, and relevant certifications (ISO, material certs, gear quality reports). The manufacturer should be willing to provide verification documentation as discussed earlier.

- Customization Capabilities: If standard slewing bearings aren’t suitable, expect the manufacturer to discuss customization options – modifying dimensions, gear parameters, sealing arrangements, or materials for specific crane or excavator needs. This includes producing customized slewing bearing worm gear slew drives if required.

- Realistic Lead Times and Logistics Support: Expect honest and achievable production lead times. The manufacturer should provide updates on order status and offer support with logistics and shipping arrangements, understanding the impact delays have on production schedules.

- Competitive Factory Pricing: While quality is paramount, working directly with the factory should offer competitive pricing by eliminating intermediary markups. However, be wary of prices that seem too good to be true, as they might reflect compromises in material or quality.

- After-Sales Support: A reliable manufacturer stands behind their product. Expect reasonable warranty terms and technical support should any issues arise after delivery or during installation of the slewing bearing.

Building a successful relationship requires effort from both sides. Procurement should provide clear, detailed specifications and operational parameters. The manufacturer should deliver a quality slewing bearing, transparent communication, and reliable service. This collaborative approach minimizes pain points and ensures the procured bearing meets the demanding requirements of crane applications, contributing to the overall success of the final equipment. Our factory focuses on building these strong, supportive relationships with clients worldwide, supplying everything from light slewing bearing high precison cross roller slewing bearing excavator slew bearing crane slewing bearing to specialized turntable bearing solutions.

Key Takeaways on Crane Slewing Bearings:

- Critical Component: The slewing bearing (or slew ring) is essential for a crane‘s ability to rotate and position heavy loads, handling complex axial, radial, and moment forces.

- Variety of Types: Choose the right bearing type (four point contact ball slewing, cross roller, double row ball slewing bearing, three row roller slewing bearing) based on load, precision, and size requirements.

- Selection is Key: Base selection on thorough load analysis, duty cycle, gear needs (internal gear slewing bearing, external gear slewing bearing, or non-geared), and operating environment.

- Quality Verification: Insist on material certifications, dimensional reports, load capacity validation, and gear quality checks (if applicable) from your supplier.

- Maintenance is Non-Negotiable: Regular maintenance, especially lubrication, seal inspection, and bolt torque checks, is vital for longevity and optimal performance and preventing failures.

- Supplier Diligence: Choose manufacturers with proven expertise, robust quality systems, good communication, technical support, and a reliable track record, especially when sourcing globally.

- Factory Collaboration: Working directly with a manufacturer offers technical advantages, customization, and potentially better pricing, but requires clear communication and defined expectations.

Understanding these aspects empowers you to make informed decisions about crane slewing bearings, ensuring the safety, reliability, and efficiency of your heavy lifting equipment. As a dedicated slewing bearing factory, we are committed to providing high-quality products and expert support for all your bearing needs.