Mastering Slewing Bearing Design: A Comprehensive Guide to Slew Engineering Excellence

2025-05-13

Slewing bearings are the unsung heroes of heavy machinery, the critical mechanical components that allow massive structures to rotate smoothly and reliably under immense load conditions. From towering cranes on construction sites to precise medical scanners and powerful wind turbines, the performance of a slewing bearing dictates the efficiency and safety of the entire system. Understanding the intricacies of slewing bearing design isn’t just an academic exercise; it’s a fundamental requirement for anyone involved in specifying, purchasing, or integrating these vital parts. As a factory owner, Allen, with years of experience in designing and manufacturing slewing bearings in China for customers across the USA, North America, Europe, and Australia, I’ve seen firsthand how a well-designed bearing can make all the difference.

This article dives deep into the world of slewing bearing engineering. We’ll explore the core principles, the different types of bearings, critical factors like load capacity and material selection, the nuances of gear design, and the importance of customization. If you’re like Mark Thompson, a company owner or procurement officer in the USA who values both quality and competitive pricing, and you’re looking to source cost-effective slewing ring bearings for your equipment, this guide is for you. We understand your concerns about load verification, material certifications, dimensional accuracy, gear quality, sealing effectiveness, corrosion resistance, and lead times. This comprehensive overview will help you navigate these complexities, make more informed purchasing decisions, and ultimately ensure the optimal performance and longevity of your machinery. Let’s slew into the details!

What Exactly is a Slewing Bearing and Why is its Design So Critical?

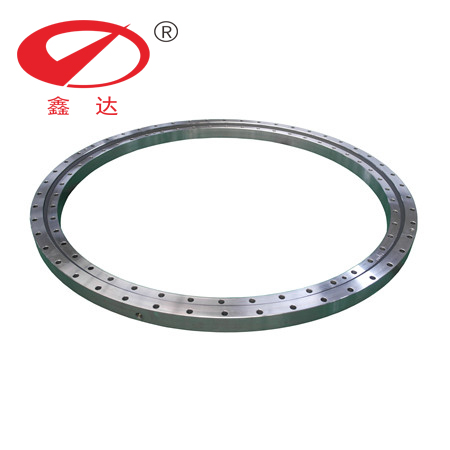

A slewing bearing, often called a slewing ring bearing or turntable bearing, is a large-diameter bearing designed to accommodate axial, radial, and moment loads, typically in a single unit. Imagine the base of an excavator or a large crane; the component that allows the upper structure to rotate smoothly while supporting its massive weight and operational forces is a slewing bearing. These bearings consist of an inner ring, an outer ring, rolling elements (either balls or rollers), and often, integral gears. The design of these bearings is incredibly critical because they are often the linchpin of very large, very expensive, and very powerful machinery. A failure in a slewing bearing can lead to catastrophic equipment failure, significant downtime, and costly repairs. Therefore, the initial design phase is paramount to ensure safety and efficiency.

The criticality of slewing bearing design stems from several factors. Firstly, these bearings must handle a complex combination of loads. It’s not just about supporting a downward thrust; they also manage side forces (radial loads) and tilting forces (moment loads). Secondly, the operating environmental conditions can be incredibly harsh, ranging from extreme temperatures and dusty construction sites to corrosive marine environments. The bearing design must account for these challenges to prevent premature wear and failure. Thirdly, many slewing bearings incorporate a gear – either external or internal – which needs to mesh perfectly with the drive pinion for smooth power transmission. Any imprecision in the gear or bearing geometry can lead to excessive vibration, noise, and rapid wear. As a manufacturer, we pay meticulous attention to every design detail to ensure each bearing meets its specific operational requirement.

Understanding the specific application is the cornerstone of good slewing bearing design. For instance, a slewing bearing for a wind turbine, which experiences continuous, dynamic loads and requires high precision for optimal energy capture, will have a different design philosophy than a bearing for a slower, intermittently used construction platform. The size, type of rolling elements, raceway geometry, material properties, sealing arrangement, and gear configuration are all tailored to the application. This attention to detail in the design phase directly translates to the bearing’s performance, durability, and overall lifecycle cost. For customers like Mark, this means receiving a bearing that not inly fits the dimension and load requirements but also offers long-term reliability.

How Do Different Types of Slewing Bearings (Ball vs. Roller) Impact Design Choices?

The choice between ball bearings and roller bearings is a fundamental design decision for slewing rings, significantly influencing their load capacity, stiffness, and suitability for different applications. Single-row ball bearing slewing rings are perhaps the most common type. They use a single row of steel balls as rolling elements and typically feature a four-point contact design. This means each ball contacts the raceway at four points, allowing the bearing to handle axial, radial, and moment loads simultaneously. These bearings are versatile and cost-effective for many applications. However, their load capacity is generally lower than that of roller bearings of a similar size. The design of the groove (raceway) in a ball bearing is critical to distribute the load effectively and ensure smooth operation.

Roller slewing bearings, on the other hand, use cylindrical or tapered rollers as their rolling elements. These bearings come in several configurations:

- Single-row crossed roller bearings: These have rollers arranged alternately at 90 degrees to each other. This design allows them to handle loads from all directions with high rigidity and accuracy, making them suitable for applications requiring high precision.

- Double-row roller bearings: These can have two rows of rollers to significantly increase load capacity, especially for axial loads.

- Three-row roller bearings: These are designed for very high loads. They typically have one row of rollers for radial loads and two rows for axial loads, providing exceptional load-carrying capacity and stiffness. The design for these bearings is more complex, but essential for heavy-duty machinery like large cranes and offshore platforms.

The design choice between ball and roller slewing bearings impacts several parameters. Roller bearings generally offer higher load capacity and greater stiffness due to the line contact (rollers) versus point contact (balls) with the raceways. This makes them better suited for applications with very high loads or where minimal deflection is critical. However, roller bearings can sometimes be more sensitive to misalignment and may require more precise mounting surfaces. The design complexity and manufacturing cost can also be higher for roller bearings, especially multi-row configurations. We often guide our customers through a comprehensive analysis of their load conditions, space constraints, and performance requirements to select the optimal bearing type. For instance, our I.1166.20.00.B Ball Slewing Bearing is an excellent example of a versatile ball bearing solution.

What Key Load Factors Must Be Considered in Slewing Bearing Design? (Axial, Radial, Moment)

When designing a slewing bearing, a thorough understanding and accurate calculation of all acting loads are absolutely crucial. These bearings are unique in their ability to handle a combination of loads simultaneously. The three primary types of loads are:

- Axial Load (Thrust Load): This is the force acting parallel to the bearing’s axis of rotation. For example, the weight of the superstructure of an excavator resting on the slewing bearing is primarily an axial load.

- Radial Load: This is the force acting perpendicular to the bearing’s axis of rotation, essentially a side load. Wind forces on a crane boom or cutting forces on a mining machine can introduce significant radial loads to the slewing bearing.

- Moment Load (Tilting Moment): This is a load that tries to tilt the bearing. It arises when forces are applied at a distance from the bearing’s centerline. Think of a crane lifting a heavy object at the end of its boom; this creates a large moment load on the slewing bearing.

Accurately determining these loads – both their magnitude and direction – is the first step in selecting or designing an appropriate slewing bearing. Engineers must consider not only static loads (when the machine is at rest) but also dynamic loads (when the machine is in operation). Dynamic loads can be much more complex, involving acceleration, deceleration, impact forces, and vibrations. The design of the slewing bearing, particularly its internal geometry, raceway profile, and the size and number of rolling elements, is directly influenced by these load calculations. An under-designed bearing will fail prematurely, while an over-designed bearing can be unnecessarily large, heavy, and expensive.

Beyond these primary loads, other factors come into play. The frequency and nature of the load (e.g., continuous, intermittent, shock loads) impact the fatigue life of the bearing. The operational speed of rotation, although often low in slewing bearing applications, can influence lubrication requirements and heat generation. As a manufacturer, we often ask for detailed application data, sometimes even a sketch or model of the equipment, to help calculate these loads accurately. This collaborative approach helps ensure that the selected or customized slewing bearing will have an adequate load capacity and provide a long service life. We aim to ensure the bearing operates without issues related to load handling, a key concern for procurement officers like Mark.

How Does Material Selection and Raceway Hardening Influence Slewing Ring Performance?

The choice of materials and the heat treatment processes, particularly raceway hardening, are fundamental to the performance, durability, and load capacity of a slewing ring bearing. The rings of a slewing bearing (both inner and outer) are typically made from high-quality carbon or alloy steels, such as 42CrMo or 50Mn. The material selection is driven by the need for strength, toughness, and machinability. The steel must be able to withstand the high contact stresses experienced in the raceways and have good wear resistance. For applications in harsh environmental conditions, such as marine or chemical processing, corrosion resistance becomes a critical factor, and specialized materials or protective coating options (like zinc plating or specialized paints) might be necessary.

The raceway is the path on which the rolling elements (balls or rollers) travel. This is where the highest stresses are concentrated. To withstand these stresses and prevent plastic deformation or premature wear, the raceways are selectively hardened. Common methods include induction hardening or flame hardening. The goal is to achieve a high surface hardness in the raceway (typically 55-62 HRC) while keeping the core of the ring material relatively softer and tougher to absorb shock loads and prevent brittle fracture. The depth and uniformity of this hardened layer are critical. If the hardening is too shallow, the bearing may fail due to subsurface fatigue. If it’s too deep or not controlled properly, it can lead to distortion or cracking. The design specification will detail the required raceway hardness and case depth, which we meticulously control during manufacturing.

The properties of the rolling elements themselves are also vital. They are usually made from through-hardened, high-carbon chromium bearing steel (like GCr15 or 100Cr6), which offers excellent hardness, wear resistance, and fatigue strength. The cages or spacers, which separate the rolling elements to prevent them from rubbing against each other and help distribute grease, can be made from steel, brass, or synthetic materials like nylon, depending on the application’s speed, temperature, and load requirements. Ensuring the right combination of material selection and heat treatment for all bearing components is key to achieving a long and reliable service lifespan, providing the structural integrity needed for demanding tasks.

Can You Explain the Importance of Gear Design in Geared Slewing Bearings? (Internal, External, Non-Geared)

Many slewing bearings are designed with an integral gear on either the inner or outer ring, allowing them to transmit rotational power. The design and quality of this gear are just as important as the bearing elements themselves for the overall performance of the machinery. There are three main configurations:

- External Gear: The gear teeth are cut on the outside diameter of one of the bearing rings (usually the outer ring). The drive pinion meshes with this external gear. This is a common configuration for applications like excavators and cranes.

- Internal Gear: The gear teeth are cut on the inside diameter of one of the bearing rings (usually the inner ring). This design offers a more compact assembly and can provide protection for the gear teeth. It’s often found in applications where space is limited or where the gear needs to be shielded from debris.

- Non-Geared: Some slewing bearings do not have an integral gear. In these cases, rotation is imparted by other means, or the bearing is used for passive swiveling.

The gear design involves several critical parameters, including the module (or diametral pitch), pressure angle, tooth profile, and the material and heat treatment of the gear teeth. The gear teeth are typically hardened to improve wear resistance and load-carrying capacity. This can be done through the same induction or flame hardening processes used for the raceways, or sometimes the entire ring (if it’s a smaller bearing) might be through-hardened if gear strength is paramount. The precision of the gear cutting is vital. Poor gear quality can lead to noisy operation, excessive vibration, high wear rates, and even tooth breakage, especially under high loads or high-speed operation (though slewing bearings are generally low-speed).

For our customers, like Mark, who are concerned about gear quality, we emphasize our adherence to strict manufacturing tolerances and quality control procedures for gear cutting and finishing. The gear must be designed to handle the required torque and ensure smooth, efficient power transmission. The choice between an internal gear, external gear, or non-geared bearing depends on the specific mechanical design of the equipment, space constraints, and the desired drive arrangement. We often work closely with our customer’s engineering teams to ensure the gear specification is perfectly matched to their drive system, preventing issues like improper backlash or interference. A well-designed and manufactured gear is essential for the longevity and reliability of the entire slewing system. Our range includes various Slewing Gear options tailored to diverse needs.

Why is Proper Sealing and Lubrication Vital for a Slewing Bearing’s Lifespan?

Proper sealing and lubrication are absolutely essential for maximizing the lifespan and maintaining the performance of any slewing bearing. These bearings often operate in very demanding environmental conditions – exposed to dust, dirt, moisture, and sometimes corrosive substances. The seal system is the first line of defense, designed to prevent contaminants from entering the bearing and to retain the grease or lubricant inside. If contaminants get into the raceway, they can cause abrasive wear, indentations, and significantly shorten the bearing’s life. If the grease escapes, the rolling elements and raceways will suffer from inadequate lubrication, leading to increased friction, heat, and eventual failure.

There are different types of seals used in slewing bearings, commonly made from nitrile rubber (NBR) or other synthetic materials, depending on the operating temperature and environmental factors. Lip seals are very common. The effectiveness of the seal design is critical. For particularly harsh environments, multiple seals or specialized seal designs might be employed. The seal must be robust enough to withstand the conditions but also designed not to cause excessive friction itself. As a manufacturer, we pay close attention to the seal groove design and the quality of the seal material to ensure optimal protection for the bearing.

Lubrication, primarily with grease, serves several functions in a slewing bearing:

- It reduces friction between the rolling elements and the raceways.

- It protects against corrosion.

- It helps to dissipate heat.

- It can provide an additional barrier against contaminants.

The type of grease, the amount, and the relubrication intervals are crucial. The bearing design must include provisions for relubrication, such as grease fittings, to allow for periodic replenishment of fresh grease. The choice of grease depends on factors like load, speed, temperature, and the operating environment. Using the wrong grease or failing to relubricate properly is a common cause of premature slewing bearing failure. We always provide clear recommendations on lubrication to help our customers ensure their bearings achieve their maximum potential service life.

How Can I Customize a Slewing Bearing to My Specific Application Requirements?

One of the significant advantages of working directly with a specialized slewing bearing manufacturer like us is the ability to customize the bearing design to meet your exact application requirements. Standard, off-the-shelf bearings are suitable for many situations, but often, unique operational demands, space constraints, or load conditions necessitate a tailored solution. Customization can range from minor modifications to a completely bespoke bearing design. This flexibility is something we pride ourselves on, especially when serving B2B clients who are integrating our bearings into their own specialized equipment.

The customization process typically begins with a comprehensive discussion of your needs. We’d want to understand:

- Load spectrum: Detailed information on axial, radial, and moment loads, including both static loads and dynamic components.

- Dimensional constraints: The available space, required inner and outer diameter, height, and any limitations on bolt circle diameters.

- Gear requirements: If a gear is needed, we’ll discuss external vs. internal, module, number of teeth, desired backlash, and hardness.

- Operating environment: Temperature range, exposure to moisture, dust, or corrosive agents. This influences material selection, seal design, and coating choices.

- Rotational speed and duty cycle.

- Mounting arrangement and required precision.

- Any specific industry standards or certifications that need to be met (e.g., ISO for bearings).

Based on this information, our engineering team can propose a customized slewing bearing design. This might involve adjusting the raceway geometry, selecting different rolling elements, modifying the ring cross-sections for optimal stiffness and strength, designing a specific gear profile, or developing a unique seal configuration. We can create detailed drawings and perform finite element analysis (FEA) to validate the design and ensure it can handle the specified loads and meet performance targets. For example, we can design bearing solutions with specific preload settings to achieve higher rigidity if the application demands it. This ability to customize according to customer needs is key to our service for clients like Mark, who may have very particular specifications for their equipment.

What Are the Critical Steps to Select the Right Slewing Bearing for My Equipment?

Selecting the right slewing bearing is a critical decision that directly impacts the performance, reliability, and cost-effectiveness of your equipment. It’s not just about finding a bearing that fits; it’s about finding one that is perfectly matched to the operational demands. Here are some critical steps we advise our customers to follow:

- Define Operating Conditions & Requirements: This is the foundation. You need a clear picture of all loads (axial, radial, moment, static, dynamic), rotational speed, duty cycle, required precision, space limitations, and the environmental conditions the bearing will face. The more detailed this information, the better.

- Calculate Combined Loads and Determine Bearing Capacity: Use the operational data to calculate the maximum combined load the bearing will experience. This will help determine the necessary static load capacity and dynamic load capacity. Remember to consider appropriate safety factors. Many bearing manufacturers, including us, provide formulas and tools to help with these calculations.

- Choose the Bearing Type: Based on the load capacity, stiffness requirements, and precision needs, decide on the type of slewing bearing: single-row ball bearing, double-row ball bearing, single-row crossed roller bearing, or multi-row roller bearing. For instance, a precision double-row ball slewing ring might be ideal for applications demanding high accuracy and moderate loads.

- Determine Gear Requirements (if any): If your application needs a geared slewing bearing, specify whether an internal gear or external gear is needed, the gear module, number of teeth, and any specific hardness or material requirements for the gear.

- Consider Sealing and Lubrication: Based on the operating environment, choose an appropriate seal configuration to prevent contamination and retain grease. Determine the lubrication type and relubrication schedule.

- Verify Mounting and Installation Requirements: Check the mounting surface flatness and rigidity. Ensure the bolt specifications (size, grade, tightening torque) are appropriate for the loads the bearing will transmit. Proper installation is key to bearing performance.

- Consult with the Manufacturer: Don’t hesitate to talk to slewing bearing specialists. As a manufacturer, we have extensive experience and can provide valuable guidance. We can review your calculations, suggest a suitable standard bearing, or discuss options to customize a bearing if needed. This is particularly important for complex applications or when you’re looking to optimize for cost and performance.

By following these steps, you can significantly increase the chances of selecting the right slewing bearing that will provide reliable service for its intended lifespan. This careful selection process addresses many of Mark Thompson’s key concerns, ensuring the chosen bearing meets the load capacity verification, dimensional accuracy, and gear quality standards he seeks.

How Do Manufacturing Precision and Quality Control Ensure Slewing Bearing Reliability?

The reliability of a slewing bearing is not just a function of its design and material selection; it is heavily dependent on the precision and quality control measures implemented during its manufacturing. Even the best bearing designs can fail prematurely if not manufactured to the required tolerances. At our factory, we understand that for customers like Mark, consistent quality and adherence to specification are paramount, especially when sourcing bearings from developing countries. This is why we have robust quality management systems in place, often compliant with ISO standards for bearings.

Key areas where manufacturing precision is critical include:

- Raceway Geometry: The profile, roundness, and surface finish of the raceways must be extremely precise. Any imperfections can lead to uneven load distribution, increased stress concentrations, and reduced fatigue life. We use advanced grinding and superfinishing techniques to achieve the required raceway quality.

- Dimensional Accuracy: The overall dimensions of the bearing, including inner and outer diameters, height, and bolt hole patterns, must conform to the design specifications. This ensures proper fit-up during installation and correct interaction with mating components.

- Gear Precision: For geared slewing bearings, the accuracy of the gear teeth (profile, pitch, lead, runout) is vital for smooth and quiet operation and efficient torque transmission. High-precision gear cutting and grinding machines are essential.

- Hardness Control: The depth and uniformity of the hardened layer on raceways and gear teeth must be tightly controlled through precise heat treatment processes and subsequent hardness testing.

Our quality control process is multi-stage, starting from the inspection of incoming raw materials (steel for rings and rolling elements, seal materials) to in-process checks at various manufacturing steps, and finally, a thorough inspection of the finished slewing bearing. This includes dimensional checks, hardness testing, raceway runout measurements, gear accuracy checks (if applicable), and clearance/ preload adjustment verification. We maintain detailed records for traceability. This commitment to precision and quality control helps us ensure that every slewing bearing leaving our factory meets the designed performance characteristics and provides the long service life our customers expect. This also helps in minimizing issues like shipment delays due to rework or quality problems, which can impact production schedules.

What Are Common Maintenance Practices to Maximize the Life of a Slewing Bearing?

While a well-designed and properly installed slewing bearing is built for durability, regular maintenance is crucial to maximize its operational lifespan and prevent unexpected failures. Neglecting maintenance can lead to costly downtime and repairs. Fortunately, slewing bearing maintenance is generally straightforward. Here are some common practices:

- Regular Lubrication: This is the most important maintenance task. Follow the manufacturer’s recommendations for the type of grease, the amount, and the relubrication intervals. Over-greasing or under-greasing can both be detrimental. Ensure fresh grease is purged through the seals to help flush out old grease and contaminants. Check for any signs of grease leakage, which might indicate a damaged seal.

- Seal Inspection: Periodically inspect the seals for any damage, wear, or detachment. Damaged seals compromise the bearing’s protection against contaminants and should be replaced promptly if possible, or the bearing monitored more closely.

- Bolt Torque Monitoring: The bolts that secure the slewing bearing to its mounting structures are critical. Over time, due to vibration and dynamic loads, bolts can loosen. Periodically check the bolt torque and re-tighten them to the manufacturer’s specified values. Loose bolts can lead to uneven load distribution on the bearing, excessive movement, and eventual failure of both the bearing and the bolts.

- Monitoring for Unusual Noise or Vibration: Listen for any unusual noises (grinding, clicking) or feel for excessive vibration during operation. These can be early indicators of bearing damage, contamination, or lubrication problems. If such symptoms appear, investigate the cause immediately.

- Checking Gear Wear (for geared bearings): If the slewing bearing has an external or internal gear, periodically inspect the gear teeth for signs of wear, pitting, or damage. Ensure proper lubrication of the gear mesh.

- Keeping the Bearing Clean: Keep the area around the slewing bearing as clean as possible to reduce the chances of contaminants entering the bearing, especially during relubrication.

By implementing a proactive maintenance schedule, you can significantly extend the service life of your slewing bearing and ensure your equipment continues to operate smoothly and efficiently. For instance, for an I.2025.50.15.D.1-R roller slewing bearing used in bucket-wheel excavators, which operates in a typically harsh environment, diligent maintenance is key to its longevity. This proactive approach helps to avoid the pain points of unexpected failures and production stoppages.

In conclusion, the design and selection of a slewing bearing is a multifaceted process that requires careful consideration of loads, operating conditions, material properties, and manufacturing precision. As a leading High Quality Slewing Ring Bearings Supplier, we are committed to providing our customers with bearings that not only meet their technical specifications but also deliver exceptional value and reliability.

Key Takeaways to Remember:

- Comprehensive Load Analysis: Accurately determine all axial, radial, and moment loads, both static and dynamic, to ensure adequate bearing capacity.

- Right Bearing Type: Select the appropriate bearing type (single/double row ball bearing, roller bearing) based on load, stiffness, and precision requirements.

- Material and Hardening Matter: Proper material selection and raceway hardening are crucial for bearing durability and wear resistance.

- Gear Design is Integral: For geared bearings, the gear type (internal/external), precision, and hardness directly impact performance.

- Seals and Lubrication are Vital: Effective seals protect against contamination, while correct lubrication minimizes friction and wear, extending the bearing’s lifespan.

- Customization Offers Solutions: Don’t hesitate to explore customized bearing designs for unique applications to optimize performance and fit.

- Precision Manufacturing Ensures Quality: High manufacturing precision and stringent quality control are essential for reliable slewing bearing performance.

- Maintenance is Key to Longevity: Regular lubrication, seal inspection, and bolt torque checks are critical maintenance tasks.