Mastering Slewing Bearing Measurement: A Guide to Bearing Design and Wear Assessment

2025-05-20

Slewing bearings are the unsung heroes in many big machines we see and use. Think of giant cranes, wind turbines, or even the precise scanners in hospitals. These machines need parts that can handle heavy loads and turn smoothly. That’s where slewing bearing components come in. This article is all about understanding how we measure these important parts, especially how we check for bearing wear. Knowing this helps keep machines running safely and for a long time. We’ll explore why accurate measurement is key, how it ties into the bearing design, and what it means to get the right slewing motion. If you want to learn how to keep your heavy machinery in top shape by understanding its core rotational components, this guide is for you!

What Exactly is a Slewing Bearing and Why is Measurement So Important?

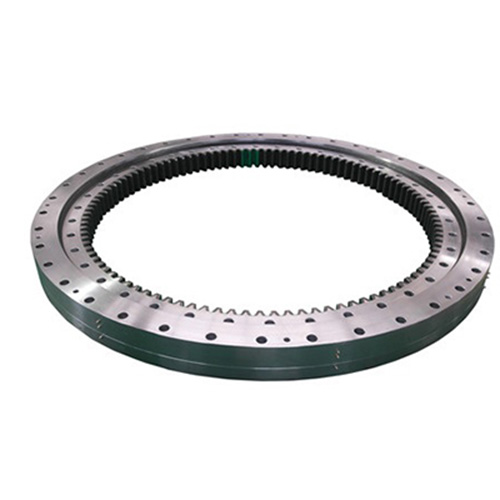

A slewing bearing, sometimes called a slewing ring, is a large-diameter bearing that can handle a combination of forces. Imagine a heavy crane arm; it needs to lift (axial load), resist toppling (moment load), and turn smoothly (radial load). A slewing bearing does all this! It’s like a giant, strong, rotating joint. These bearings are crucial in many industries, from construction equipment where they allow excavators to slew their upper structure, to wind turbines where they help blades face the wind. You’ll also find them in robotics and medical scanners requiring precision movement.

So, why is measurement so vital for these components?

First, measurement ensures the slewing bearing fits perfectly during installation. Even a tiny deviation in size or alignment can cause big problems. Think of it like a door hinge; if it’s not aligned, the door won’t open or close properly. For a slewing bearing, poor fitment can lead to uneven wear, increased stress, and ultimately, failure. This downtime can be very costly. As a manufacturer, we, Allen from Xinda Slewing Bearing, always stress the importance of precise initial measurement to our clients.

Second, ongoing measurement helps us track the health of the slewing bearing over its service life. By measuring things like tilt or changes in rotational smoothness, we can detect early signs of wear. This allows for planned maintenance of the bearing rather than unexpected breakdowns. For a company owner like Mark Thompson, who relies on dependable machinery, understanding these measurements means he can better predict maintenance schedules and avoid costly operational surprises. The forces acting on the bearing, whether static loads or dynamic loads, contribute to wear, and measurement is our window into how the bearing is coping.

How Do We Define Slewing Ring Wear Measurement and Its Significance?

Slewing ring wear measurement is the process of checking how much a slewing ring (another term for slewing bearing) has worn down over time. Think of it like checking the tread on your car tires. Just as worn tires can be dangerous, a worn slewing bearing can lead to machine failure. This wear measurement isn’t just a single check; it involves looking at several things. A key aspect is measuring the tilting clearance. This tells us how much the slewing bearing can wobble or tilt. As the internal parts (like the raceway where ball bearings or rollers move) wear down, this wobble can increase.

The significance of wear measurement is huge. For one, it’s a big safety factor. If a slewing bearing on a crane fails, the upper structure could become unstable. That’s a major risk. Secondly, it saves money. Catching wear early means you might only need to adjust or re-lubricate the slewing bearing, or plan for a replacement during scheduled downtime. If you wait until it fails completely, you could damage other parts of the machine, leading to much more expensive repairs. This is a major concern for procurement officers like Mark Thompson, who need to balance cost-effectiveness with reliability. Consistent wear measurement ensures that the slewing bearing continues to support the rated and working loads effectively.

As Allen, speaking from our factory’s experience, we’ve seen that regular wear measurement can significantly extend the operational life of equipment. It helps in understanding if the operating bearing forces are within the bearing design limits or if there’s an unforeseen load condition causing premature wear. It’s a proactive approach rather than a reactive one, crucial for heavy machinery operating under harsh external conditions. This is particularly true for a Precision double-row ball slewing ring where precision is paramount.

What are the Key Parameters for Slewing Bearing Inspection?

When we perform an inspection on a slewing bearing, we look at several key things to understand its condition. It’s like a doctor’s check-up for the bearing. Here are some important parameters:

- Tilting Clearance Measurement: This is a primary indicator of wear in the raceway and rolling elements. We measure how much the slewing bearing can tilt under a specific load. An increase in this value often signals wear.

- Rotational Torque: We check how much force it takes to turn the slewing bearing. If it becomes harder to turn, or if the torque is jerky, it could mean problems with lubrication, contamination, or damage to the raceways or rolling elements.

- Gear Condition (if applicable): Many slewing bearing units have gear teeth on the outer ring or inner ring for rotation. We inspect these tooth surfaces for wear, pitting, cracks, or signs of improper pinion and gear location meshing. This is vital for applications like excavators that rely on the geared outer race.

- Seal Integrity: The seal is super important. It keeps grease in and dirt and water out. We check the outer seal and any other seals for damage, wear, or displacement. A failed seal can lead to rapid contamination and failure of the slewing bearing.

- Bolt Torque: The threaded bolts that hold the slewing bearing to the upper structure and lower structure must be tightened correctly. We check if these bolts are at their specified torque values. Loose bolts can cause movement and damage the bearing or mounting surfaces.

- Lubrication Analysis: We look at the condition of the grease. Is it dirty? Does it have metal particles? This can tell us a lot about what’s happening inside the slewing bearing. Proper lubrication is critical.

- Noise and Vibration: Experienced technicians listen for unusual noises or feel for excessive vibrations during operation. These can be early warnings of developing problems within the slewing bearing.

Each of these parameters gives us a piece of the puzzle about the slewing bearing’s health. Regular inspection helps ensure the service factor remains appropriate for the application.

Understanding the Importance of the Right Slewing Motion and Bearing Design

Getting the right slewing motion is essential for any machine that uses a slewing bearing. "Right slewing" means the rotation is smooth, precise, and happens with the correct amount of force or speed. If the slewing motion is jerky, too stiff, or has too much play, it can affect the machine’s performance and even its safety. For example, a crane needs to slew smoothly to place loads accurately. An excavator needs responsive slewing to dig efficiently. The quality of this motion is directly tied to the bearing design and its current condition.

The bearing design itself is a complex process. Engineers consider many factors:

- Loads: What kind of forces will the slewing bearing experience? This includes axial (up and down), radial (side to side), and tilt (moment) loads. They also consider if these are static loads or dynamic loads, and the potential for extreme or impact loads.

- Rotational Speed: How fast does the slewing bearing need to turn?

- Operating Environment: Will it be exposed to dirt, water, extreme temperatures, or corrosive substances? This influences the choice of materials, seal type, and coating.

- Size and Space Constraints: The slewing bearing must fit into the machine’s design. The diameter and cross-section are key considerations.

- Precision Requirements: Some applications, like robotics or medical equipment, need very high precision with minimal play. Others might be less demanding.

As a manufacturer, we at Xinda Slewing Bearing often use tools like finite element analysis (FEA) to simulate how a slewing bearing design will perform under various load condition scenarios. This helps us optimize the design features, such as the raceway geometry and the number and size of rolling elements (like ball bearings or rollers). Choosing the right slewing bearing means matching these design characteristics to the specific application needs. If the design isn’t right, or if the bearing isn’t maintained, you won’t get that crucial right slewing motion.

How Does Tilt Measurement Indicate Bearing Wear in Slewing Rings?

Tilt measurement is one of the most common and effective ways to assess bearing wear in slewing rings (or slewing bearing units). Imagine the slewing ring as two rings, one fixed (e.g., to the lower structure of a crane) and one rotating (e.g., supporting the upper structure). Between these rings are rolling elements – either ball bearings or rollers – that run in carefully shaped grooves called raceways. When the slewing bearing is new, these parts fit together snugly, allowing smooth rotation with very little wobble or tilt.

As the slewing bearing operates over time, especially under high loads, the raceways and rolling elements naturally wear down. This wear creates extra space inside the bearing. Tilt measurement quantifies this extra space. It’s typically done by applying a known force or moment to one part of the slewing bearing (e.g., the rotating ring) and measuring how much it deflects or "tilts" relative to the fixed ring. This measurement is often taken at several points around the diameter of the slewing bearing. An increase in this tilting clearance over time is a direct indication that wear is occurring within the raceway.

Why is this important? Excessive tilt can lead to several problems:

- Reduced Accuracy: For machines needing precision, like robotics or antennas, too much tilt means the machine can’t position itself accurately.

- Increased Stress: More tilt can change how loads are distributed within the slewing bearing, potentially overloading certain parts and accelerating wear.

- Gear Problems: If the slewing bearing has gear teeth on the outer ring (or inner), excessive tilt can cause poor meshing with the drive pinion. This leads to rapid gear wear and potential tooth failure.

- Safety Risks: In extreme cases, if the wear and tilt become too great, the slewing bearing could fail catastrophically.

Therefore, regularly performing a tilt measurement is a cornerstone of good maintenance of the bearing. It allows operators to track the progression of bearing wear and plan for replacement before serious issues arise. This is much better than waiting for the slewing bearing to fail unexpectedly.

Can You Explain the Load Curve and Its Role in Slewing Bearing Selection?

A load curve, also known as a capacity curve or bearing’s rating curve, is a super important graph provided by the slewing bearing manufacturer. It shows the maximum loads a specific slewing bearing can safely handle. Think of it like a strength chart for the bearing. This curve usually plots the relationship between the axial load (the up-and-down force), the radial load (the side-to-side force), and the tilt or moment load (the toppling force) that the slewing bearing can withstand simultaneously.

Here’s how it works in selecting the right slewing bearing:

- Determine Your Loads: First, engineers for the machine (like a crane or excavator) must calculate all the forces acting on the slewing bearing during its operational life. This includes normal loads, but also considering potential for extreme or impact loads. These forces create a specific load condition or a set of operating bearing forces.

- Plot Your Point: The engineer then takes these calculated axial, radial, and moment loads for their application and plots them as a point on the load curve chart for a potential slewing bearing.

- Check Your Position:

- If the plotted point for your application falls below the curve (or within the safe operating area defined by the curve), then that specific slewing bearing might be suitable in terms of load capacity.

- If the point falls on or above the curve, that slewing bearing is not strong enough and should not be used. It would be overloaded.

- Consider the Service Factor: The load curve often represents the static loads capacity or a specific dynamic capacity. Engineers also apply a service factor. This is a safety margin to account for things like vibration, shock loads, or how critical the application is. So, the actual working loads, when multiplied by the service factor, must still fall below the curve.

Using the load curve is a critical step to make a preliminary selection for a slewing bearing. You do a preliminary selection by comparing your needs against the bearing catalog data. It ensures that the chosen slewing bearing has enough strength for the job. Choosing a bearing that’s too small (undersized) will lead to quick failure. Choosing one that’s massively oversized might be too expensive or too big to fit. The load curve helps find that optimal balance, ensuring the slewing bearing designs can handle the rated and working loads. Many types of bearings, including Single Row -Ball Bearing Slewing Rings, have such curves.

What Common Issues are Found During Slewing Bearing Inspection, like Contamination or Lubrication Problems?

During a slewing bearing inspection, several common problems can pop up. Catching these early is key to preventing bigger, more expensive issues down the road. Two of the biggest culprits are contamination and lubrication problems.

Contamination:

This is when dirt, dust, water, metal particles, or other unwanted stuff gets inside the slewing bearing.

- How it happens: Often, it’s because the seal is damaged, worn out, or improperly installed. Sometimes, harsh external conditions can overwhelm even a good seal.

- What it does: Contamination acts like sandpaper inside the slewing bearing. The abrasive particles get ground between the rolling elements (like ball bearings) and the raceway, causing rapid wear. Water can cause rust and corrosion, which also damages surfaces and can reduce the hardness of the material. Metal particles might indicate severe internal wear or damage elsewhere in the system.

- Signs: You might see dirty or discolored grease oozing from the seal, or the grease might feel gritty. The slewing bearing might also become noisy or harder to turn.

Lubrication Problems:

Proper lubrication is like the lifeblood of a slewing bearing. It reduces friction, prevents wear, protects against corrosion, and helps dissipate heat.

- Too little grease: If there’s not enough grease, metal parts rub directly against each other. This causes high friction, heat, and rapid wear.

- Too much grease: Over-greasing can sometimes damage seals by forcing them out of place. It can also cause the slewing bearing to run hotter due to churning losses.

- Wrong type of grease: Different slewing bearing applications (considering speed, load, temperature) need different types of grease. Using the wrong kind might not provide enough protection or might break down too quickly.

- Old or degraded grease: Over time, grease can break down, lose its lubricating properties, or become contaminated. This is why regular re-lubrication with fresh, clean grease is important.

- Signs: The slewing bearing might run hot, make unusual noises (squealing, grinding), or become difficult to rotate. You might also see grease that looks dry, caked, or separated.

Other common issues found during inspection include:

- Bolt Loosening: The threaded bolts holding the slewing bearing can loosen due to vibration.

- Gear Wear: For geared slewing bearing units, excessive tooth wear or damage.

- Cracks: Cracks in the rings, though less common, are a very serious issue.

- Corrosion: Rust or other forms of corrosion on bearing surfaces.

Regular inspection and addressing these issues promptly is vital for the service life of any slewing bearing.

The Role of Ball Bearings and Roller Bearings in Slewing Applications: A Closer Look

When we talk about slewing bearing units, the rolling elements inside them – the parts that allow the smooth rotation – are typically either ball bearings or cylindrical/tapered rollers. The choice between these depends heavily on the bearing design requirements and the specific application. Both types are essential for the right slewing motion.

Ball Bearings in Slewing Rings:

- How they work: Ball bearings are spherical. In a slewing bearing, they typically run in specially shaped grooves (raceways) in the inner and outer rings. A common configuration is the "four-point contact" ball bearing, where each ball touches the raceways at four points. This allows a single row of balls to handle a combination of axial, radial, and tilt (moment) loads.

- Advantages:

- Good for moderate loads and relatively higher rotational speed compared to some roller designs.

- Can offer very smooth rotation.

- Often more compact for a given load capacity compared to some multi-row roller designs.

- Common Types:

- Single-row four-point contact ball bearings.

- Double-row ball bearings (can handle higher loads, especially tilting moments).

- Applications: Often used in lighter to medium-duty applications like smaller cranes, aerial work platforms, robotics, and some industrial turntables. You can find excellent examples like the I.1166.20.00.B Ball Slewing Bearing.

Roller Bearings in Slewing Rings:

- How they work: Roller bearings use cylindrical, tapered, or crossed rollers. These rollers have a larger contact area with the raceways compared to ball bearings.

- Advantages:

- Excellent for very high loads, especially heavy axial and tilt loads. The larger contact area distributes the load more effectively.

- Can offer high stiffness, meaning less deflection under load.

- Common Types:

- Single-row crossed roller bearings: Cylindrical rollers are arranged at 90 degrees to each other. This design can handle loads from all directions.

- Three-row roller bearings: These are heavy-duty champions, often with one row for radial loads and two rows for axial and tilt loads. They are used in the largest equipment.

- Applications: Ideal for heavy-duty applications like large excavators, mining shovels, heavy-lift cranes, tunnel boring machines, and large wind turbines. The I.2025.50.15.D.1-R roller slewing bearing is a great example for such demanding jobs.

Both ball bearings and roller bearings have their place in slewing bearing designs. The measurement of wear and tilting clearance is critical for both types to ensure they continue to perform as intended and support the upper structure safely. The initial sizing and selection process, guided by the load curve and application needs, will determine which type of rolling element is most suitable.

How Can We Ensure Accurate Measurement for Different Slewing Bearing Sizes and Styles?

Ensuring accurate measurement for slewing bearing components, regardless of their size or style (bearing styles and cross-sections can vary greatly), is all about using the right tools, techniques, and having a consistent process. It’s a bit like tailoring a suit; you need precise measurements for a good fit, and the tools might change slightly if you’re measuring for a small jacket versus a large overcoat.

Here are key ways to ensure accuracy:

- Use Calibrated Measuring Tools: This is fundamental. Tools like dial indicators, feeler gauges, depth micrometers, and specialized tilt measurement devices must be regularly calibrated and in good condition. An inaccurate tool will give an inaccurate measurement, leading to wrong conclusions about the slewing bearing‘s health.

- Follow Manufacturer’s Procedures: The slewing bearing manufacturer (like us, Xinda Slewing Bearing) usually provides specific guidelines on how to measure wear, tilting clearance, and other parameters for their products. These procedures are designed for that specific bearing design and should be followed closely.

- Consistent Measurement Points: For tilt measurement, for example, always measure at the same designated points around the slewing bearing diameter. This consistency allows for reliable comparison of measurements over time, making it easier to spot trends in bearing wear. Mark these points if necessary.

- Controlled Conditions (Where Possible): Temperature changes can affect the size of metal parts. While it’s often not practical to control the environment in the field, be aware of this. If very precise measurement is needed (e.g., during installation or a detailed inspection), try to do it when the slewing bearing and surrounding structure are at a stable temperature.

- Cleanliness: Ensure the areas where you’re taking measurements are clean. Dirt or debris can throw off your readings, especially when measuring very small clearances or surface profiles of a tooth.

- Proper Tool Application: Know how to use your measuring tools correctly. For instance, when using a dial indicator for tilt measurement, ensure it’s securely mounted and its plunger is perpendicular to the surface being measured. The offset or angle of the tool can affect the reading.

- Training and Experience: Technicians performing the measurement should be properly trained. Experience helps them understand what "normal" looks like for a particular slewing bearing and to spot subtle signs of trouble. They learn to feel the difference between a smooth rotational movement and one with issues.

- Record Keeping: Keep detailed records of all measurements, including the date, the slewing bearing identification, the parameter measured, the readings, and the tools used. This historical data is invaluable for tracking wear rates and predicting when maintenance of the bearing or replacement might be needed.

Whether it’s a compact slewing bearing for robotics or a massive ring bearing for a wind turbine, the principles of accurate measurement remain the same. It’s about precision, consistency, and understanding what the numbers are telling you about the operational health of the slewing bearing. Adapting the specific technique to the size and type, like those found on our main products page, ensures reliable data.

Practical Tips for Maintenance of the Bearing and Prolonging Slewing Bearing Service Life

Good maintenance of the bearing is absolutely essential to get the longest possible service life out of your slewing bearing and keep your machinery running smoothly. It’s not just about fixing things when they break; it’s about preventing problems in the first place. Here are some practical tips, drawing on our experience at Xinda Slewing Bearing:

- Regular Lubrication is King:

- Follow the Schedule: Stick to the re-lubrication intervals recommended by the slewing bearing manufacturer. This schedule depends on the operating environment, load, and speed.

- Use the Right Grease: Ensure you’re using the correct type and grade of grease specified for your slewing bearing and application. Using the wrong grease can be as bad as no grease at all.

- Clean Grease Fittings: Before applying new grease, wipe the grease fittings clean to prevent injecting contamination into the slewing bearing.

- Purge Old Grease (Sometimes): When re-lubricating, add enough fresh grease so that a little bit of the old grease purges out past the seal. This helps flush out contaminants. But don’t overdo it, as excessive pressure can damage the seal.

- Keep an Eye on Seals:

- Regular Inspection: Check the outer seal (and internal seals if visible) for any signs of damage, wear, cracking, or displacement. A damaged seal is an open invitation for contamination.

- Protect Seals: During machine operation or cleaning, try to protect the seals from direct impact, high-pressure washing, or harsh chemicals unless the slewing bearing is designed for such conditions. Consider an external shroud if the operating environment is particularly aggressive.

- Monitor Bolt Torque:

- Check Regularly: The threaded bolts that secure the slewing bearing to the upper structure and lower structure can loosen over time due to vibration and dynamic loads. Check their torque periodically according to the machine manufacturer’s specifications.

- Proper Tightening Sequence: When installing or re-tightening bolts for any mounting arrangements, use the correct crisscross pattern and torque values to ensure even clamping force. This is critical for proper bearing and retaining bolts function.

- Listen and Observe:

- Unusual Noises: Pay attention to any new or unusual noises coming from the slewing bearing during operation – grinding, clicking, or screeching can indicate a problem.

- Jerky Motion: If the rotational motion becomes jerky, stiff, or has excessive play, investigate immediately. This could indicate issues with lubrication, contamination, or internal wear.

- Perform Wear Measurements:

- Track Tilting Clearance: Regularly measure the tilting clearance as discussed earlier. This is a key indicator of internal raceway wear.

- Inspect Gears: If your slewing bearing has a geared outer race (or inner), regularly inspect the tooth condition and the mesh with the drive pinion and gear location.

- Maintain a Clean Operating Environment (As Much as Possible):

- While some machines operate in inherently dirty conditions, try to minimize the buildup of debris around the slewing bearing.

- Keep Good Records:

- Log all maintenance activities, including lubrication dates, grease type used, measurement readings, and any observations. This history helps in troubleshooting and planning future maintenance.

By following these tips, you can significantly reduce downtime, extend the service life of your slewing bearing, and ensure safer, more reliable operation of your equipment. It’s an investment that pays off in the long run for any owner like Mark Thompson concerned about operational efficiency.

Key Takeaways to Remember:

- Slewing bearings are critical components for handling combined loads and enabling rotation in heavy machinery.

- Regular measurement, especially tilt measurement and wear measurement, is vital for assessing the health of a slewing bearing.

- Understanding the load curve is crucial for selecting the right slewing bearing with the appropriate service factor.

- Contamination and improper lubrication are major enemies of slewing bearing longevity; diligent seal checks and greasing are key.

- The choice between ball bearings and roller bearings in a slewing ring depends on the specific load, speed, and precision requirements of the application.

- Consistent inspection procedures, including checking bolt torque and gear condition, help prevent unexpected failures and costly downtime.

- The bearing design, installation, and ongoing maintenance of the bearing all play crucial roles in achieving the desired right slewing motion and maximizing service life.

- Always refer to the manufacturer’s guidelines for specific measurement and maintenance procedures for your slewing bearing.