The Ultimate Guide to Slewing Ring Bearings for Your Welding Positioner: An Insider’s Look

2025-07-18

As a procurement officer or company owner, you know that the performance of your heavy machinery hinges on the quality of its components. This is especially true for welding positioners, where precision, stability, and smooth rotation are non-negotiable. The heart of this rotation is the slewing ring bearing. Choosing the right one can feel like a high-stakes decision, and frankly, it is. A poor choice can lead to production downtime, safety hazards, and costly repairs.

This article is your comprehensive guide to navigating the world of slewing rings for welding applications. My name is Allen, and as the owner of a factory specializing in designing and manufacturing these critical components for decades, I’ve worked with countless customers like you. I understand the challenges you face—from verifying load capacities to dealing with communication gaps and shipment delays. Here, I’ll share my first-hand experience to help you make informed, confident decisions. We will explore the different types of bearings, what to look for in a quality manufacturer, how to verify technical specifications, and why a strong supplier relationship is your greatest asset.

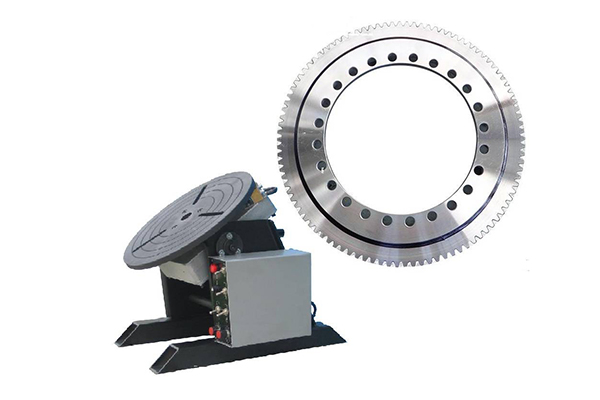

What is a Slewing Bearing and Why is it the Core of a Welding Positioner?

At its most basic, a slewing bearing is a large-diameter rotational rolling-element bearing that is designed to handle a complex mix of loads. Think of it as the sophisticated, heavy-duty cousin of the small bearings you might find in a bicycle wheel. Instead of just handling a load in one direction, a slewing bearing can simultaneously manage axial (vertical) forces, radial (horizontal) forces, and tilting moment loads. This ability to handle combined forces is what makes it indispensable for a vast range of industrial machinery, from cranes and excavators to wind turbines and, of course, the welding positioner.

For a welding positioner or welding manipulator, the slewing ring bearing is the component that allows the worktable to tilt and rotate with precision. This controlled movement is critical. It enables the welder to position the workpiece at the optimal angle for a consistent, high-quality weld without having to manually reposition the entire assembly. The bearing acts as the pivot point, supporting the entire weight of the workpiece and the worktable while ensuring the rotation is smooth and free of judder. A well-chosen bearing slewing ring bearing directly translates to better weld quality, increased efficiency, and a safer working environment.

The entire frame and worktable of the welding positioner rely on this single component for movement. The slewing motion must be precise to allow for automated or manual welding processes to be carried out flawlessly. Therefore, the selection of the correct slewing bearing is not just a mechanical choice; it’s a decision that impacts the final product quality and overall productivity of the welding operation.

How Do You Find a Professional and Reliable Slewing Bearing Supplier?

Finding the right supplier can be the most challenging part of the procurement process. For a seasoned procurement officer like Mark Thompson in the USA, who often sources from developing countries, the concerns are always the same: quality, communication, and reliability. In my experience as a manufacturer exporting to North America and Europe, building trust is paramount. A good supplier doesn’t just sell you a product; they become a partner in your production process.

First, look for a factory with a proven track record, not just a trading company. A true manufacturer has direct control over the manufacturing process, from raw material sourcing to final inspection. This is crucial for quality assurance. Ask for a virtual or, if possible, an in-person tour of their facilities. Look for modern machinery, organized production lines, and a dedicated quality control department. A company that is proud of its operations will be happy to show you.

Secondly, evaluate their technical expertise. A professional supplier should have an experienced engineering team that can discuss your specific application and need. They should ask you questions about your load requirements, duty cycle, and operating environment. If a potential supplier only wants to talk about price, it’s a red flag. At our company, XZWD, we believe the technical discussion comes first. We want to understand your challenges to ensure the bearing we provide is not just a component, but a solution. This approach helps avoid the common pain point of receiving a bearing that fails to meet dimensional or performance specifications.

What are the Main Types of Slewing Rings for Welding Applications?

The term "slewing bearing" covers a family of products, each with a unique design suited for different applications. For a welding positioner, the choice depends largely on the weight of the workpieces and the precision required. Here are the most common types you’ll encounter:

-

Single Row Four Point Contact Ball Slewing Bearing: This is the most common and versatile type. It uses a single row of balls that make four point contact with the raceways. This design allows it to handle axial, radial, and tilting moment loads simultaneously. It’s an excellent choice for light to medium-duty welding positioners due to its compact structure and cost-effectiveness. The I.1166.20.00.B Ball Slewing Bearing is a great example of this widely used product.

-

Single Row Crossed Roller Slewing Bearing: For applications requiring higher stiffness and greater load-carrying capacity, the crossed roller bearing is a superior option. It features a single row of cylindrical rollers arranged in a crisscross pattern. This arrangement provides a larger contact area, resulting in less deformation under load and more precise rotation.

-

Double Row Ball Slewing Bearing: This design uses two rows of steel balls, typically with one row handling the primary axial and tilting loads and the other handling radial loads. It’s suitable for heavier-duty welding positioners and manipulators where the loads exceed the capacity of a single row ball slewing bearing.

-

Three Row Roller Slewing Bearing: This is the king of high load capacity. It features three independent rows of rollers, each designed to handle a specific type of force (one for radial, and two for axial and tilting). This robust structure is reserved for the largest industrial equipment, such as massive welding positioner systems in the shipbuilding or mining industry.

Here is a simple table to summarize:

| Bearing Type | Load Capacity | Precision | Common Application |

|---|---|---|---|

| Single Row Ball | Moderate | Good | General Purpose Welding Positioners |

| Single Row Roller | High | Very Good | Precision Welding, Robotics |

| Double Row Ball | High | Good | Heavy-Duty Welding Positioners |

| Three Row Roller | Very High | Excellent | Extremely Large & Heavy Workpieces |

Can a Standard Slewing Bearing Handle the Demands of a Weld Operation?

This is a question I hear a lot. The short answer is yes, but with a crucial caveat: it must be the right standard bearing. The environment of a weld operation is harsh. It involves not just the load of the workpiece, but also heat, weld spatter, and fine dust particles. A generic, off-the-shelf slewing bearing might not be up to the task. A proper slewing bearing for welding applications needs specific features.

The first consideration is load. You must have a clear understanding of the maximum weight of your workpiece and the tilting moments it will generate. We always request this data from our customers to perform a load analysis and ensure the selected bearing has a sufficient safety factor. Providing a bearing that is underrated for the application is a recipe for premature failure. The second critical factor is sealing. A robust sealing system is essential to prevent contaminants like weld spatter and grinding dust from entering the raceway. Contamination is a leading cause of bearing failure. We offer various sealing options, from standard nitrile rubber seals to more advanced labyrinth seals, to match the harshness of the industrial environment.

Finally, the material and heat treatment are paramount. The rings of our slewing rings are typically made from high-quality quenched and tempered steel, such as 42CrMo or 50Mn. The raceways then undergo induction hardening to achieve a high surface hardness, ensuring a long service life even under continuous slewing motion. A standard, uncertified bearing may use inferior steel or have inconsistent heat treatment, leading to rapid wear and tear.

What is the Role of the Internal Gear in a Slewing Drive System?

Many slewing rings come with an integrated gear. This gear is what allows the bearing to be rotated by a motor-driven pinion, forming a complete slewing drive system. This integration simplifies the overall design of the machinery, reduces assembly time, and creates a more compact and reliable drive mechanism. For a welding positioner, the gear is what enables the precise, controlled rotation of the worktable.

You typically have three choices for the gear configuration:

- Internal Gear: The gear teeth are cut on the inner diameter of one of the bearing rings. This is a very popular option for welding positioners because it offers better protection for the gear teeth from external damage and contamination. The pinion is mounted inside the bearing, creating a clean, compact slewing drive. The bearing internal design is often preferred for safety and durability.

- External Gear: The gear teeth are on the outer diameter. This configuration makes the gear more accessible for inspection and maintenance but also leaves it more exposed.

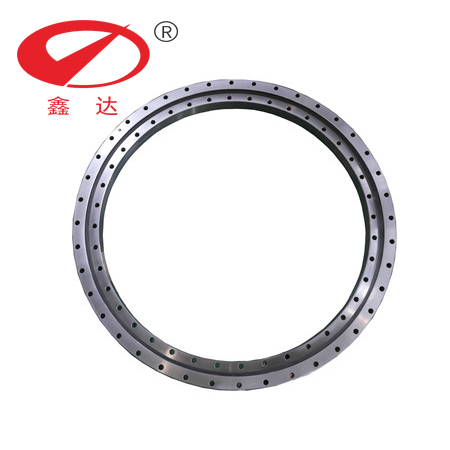

- Non-Geared: Some applications use an external drive mechanism, such as a belt or chain, and therefore do not require a gear on the slewing bearing itself.

The quality of the gear is just as important as the bearing itself. The gear teeth must be precisely machined and, in many cases, hardened to withstand the torque and wear from the drive pinion. When you request a geared slewing ring bearing, we always confirm the module, pressure angle, and required precision level of the gear to ensure it mates perfectly with your drive system.

How Can You Be Sure of the Quality and Material of the Product You Buy?

This is a critical pain point for any procurement officer buying components from overseas. You need more than just a promise; you need proof. A reputable manufacturer will have a multi-stage quality control process and be transparent about it. At our XZWD factory, every slewing bearing goes through a rigorous inspection protocol.

First, demand material certifications. We provide mill test reports for the raw steel used for the bearing rings, confirming its chemical composition and mechanical properties. This is your first line of defense against substandard materials. Second, ask about the heat treatment process. The raceways of the slewing bearing must be hardened to handle the high contact stresses. We provide reports showing the hardness depth and pattern on the race, ensuring it meets the design specification.

Third, dimensional accuracy is key. The product must fit your equipment. We provide a full dimensional inspection report with every bearing, checking everything from the bore and outer diameters to the gear tooth profile and mounting hole locations. Finally, for a slewing ring bearing for welding, we understand the importance of reliability. We perform non-destructive testing (NDT) on critical areas to check for any subsurface flaws. This complete documentation package gives our customers peace of mind and the assurance that the product they receive meets every requirement. When you buy from us, you buy a fully certified and tested bearing.

Why is Strong Communication with Your Manufacturer a Basic Need?

Inefficient communication is one of the most frustrating pain points in international procurement. It can lead to misunderstandings about specifications, shipment delays that halt your production line, and a general lack of confidence in your supplier. From my perspective, communication is the foundation of a successful business relationship. It’s a basic need, not a luxury.

A professional manufacturer will assign you a dedicated point of contact who is not only fluent in your language but also has a deep understanding of the product and your application. This person acts as your advocate within the factory, ensuring your technical requirements are understood by the engineering team and that you receive timely updates on your order status. When a customer like Mark has a question, he shouldn’t have to wait days for a response that has been passed through multiple departments.

"For a procurement officer, a delayed shipment isn’t just an inconvenience; it’s a production line halt. That’s why we prioritize transparent timelines and proactive communication. If there’s a potential issue, our customers are the first to know, not the last." – Allen, Factory Owner

We leverage modern communication tools to stay in close contact with our clients, providing regular updates with photos and inspection reports. This transparency builds trust and helps prevent the costly delays that can plague international supply chains. A good supplier doesn’t just take your order; they partner with you from the initial request to the final delivery.

Are There Light Weight and Compact Slewing Bearing Options Available?

Absolutely. Not every welding positioner is a massive, multi-ton piece of machinery. There is a growing need for smaller, more portable welding manipulators, robotic welding cells, and light-duty turntables. For these applications, a standard heavy-duty slewing bearing would be overkill—too big, too heavy, and too expensive. This is where light weight and flanged slewing rings come into play.

These bearings are designed with a much thinner cross-section, which significantly reduces their weight and profile. Our Interchange Series IMO Slewing Rings are a perfect example. They provide excellent rotational performance in a very compact structure. Some designs incorporate a flange on the inner or outer ring, which simplifies mounting and eliminates the need for additional housing components, making them very easy to install.

This category of light weight slew bearings is ideal for applications where space is limited and every kilogram matters. They use the same high-quality materials and manufacturing principles as their larger counterparts, including hardened raceways and precise four point contact ball arrangements, just in a more streamlined package. They offer a fantastic balance of performance, weight, and price for the right application.

How Does the Internal Structure of a Bearing Affect Performance?

The external dimensions of two slewing bearings might look identical, but their performance and lifespan can be vastly different. The secret lies in the bearing internal structure and the quality of its components. The engineering behind the raceway geometry, the rolling elements, and the separator is what defines the bearing’s true capabilities.

The shape of the raceway—the path where the balls or rollers move—is meticulously designed to distribute the load evenly. An improperly designed race will create stress concentrations, leading to premature metal fatigue and failure. The precision of the rolling elements themselves is also critical. We use high-grade steel balls or rollers that are sorted to have extremely tight dimensional tolerances. This ensures that the load is shared equally among all the rolling elements, maximizing the bearing’s capacity.

The separator, or cage, which keeps the rolling elements evenly spaced, also plays an important role. It prevents the balls or rollers from rubbing against each other, which would create friction and wear. In high-speed or high-precision applications, the design and material of the separator are carefully chosen to ensure smooth, reliable rotation. This attention to the details of the bearing internal design is what separates a high-performance slewing bearing, like our I.2025.50.15.D.1-R roller slewing bearing, from a generic one.

Need a Custom Solution? How to Send Your Message for a Quick Response

While there is a wide range of standard slewing rings available, sometimes your application has a unique requirement. Perhaps you need a non-standard mounting hole pattern, a special gear ratio, or a bearing made from a specific material for a corrosive environment. In these cases, you need a custom design.

This is another area where working directly with a factory like XZWD is a major advantage. Our engineering team specializes in developing custom slewing bearing solutions. The process is straightforward. The best way to start is to send your message to our contact team with as much detail as possible.

To help us provide a fast and accurate response, please include the following information in your request:

- The type of bearing you need (e.g., single row ball, crossed roller).

- Key dimensions: inner diameter, outer diameter, and height.

- Load data: the axial force, radial force, and tilting moment the bearing must support.

- Gear requirements: internal or external, module, number of teeth, or any other relevant specs.

- Any special requirements, such as specific materials, sealing, or operating conditions.

You can easily find our contact information on our website, like the page for our Precision double-row ball slewing ring, and our team will work with you to create a complete technical drawing and proposal. We are here to turn your unique challenge into a reliable, high-quality slewing bearing.

Key Takeaways for Your Next Purchase

To complete our guide, here are the most important things to remember when sourcing a slewing ring bearing for your welding positioner:

- Partner with a True Manufacturer: Work directly with a factory, not just a trader, to ensure quality control and technical support.

- Match the Bearing to the Load: Always choose a slewing bearing type (ball slewing, roller, single or multi-row) whose capacity safely exceeds your maximum operational loads.

- Verify Quality with Documentation: Insist on material certifications, heat treatment reports, and full dimensional inspection reports for every slewing bearing you buy.

- Prioritize Communication: A responsive, knowledgeable supplier who provides timely updates is invaluable for avoiding production delays.

- Don’t Overlook the Gear: The quality and precision of the integrated gear are critical for the performance of your slewing drive system.

- Consider Customization: If a standard product doesn’t fit, don’t hesitate to request a custom-designed slewing bearing tailored to your exact need.