What Are the Parts of a Slewing Bearing?

2024-08-20

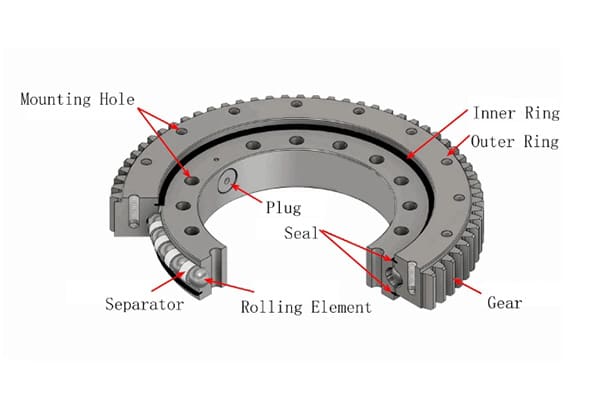

Slewing bearings are crucial components in various types of heavy machinery, from cranes and excavators to wind turbines and radar systems. These bearings enable the rotational movement of heavy equipment, making them essential for operations that require precision and stability. Understanding the parts of a slewing bearing is key to appreciating its function and importance in these applications.

Overview of Slewing Bearings

A slewing bearing, also known as a slewing ring, is a large bearing that can support heavy loads while allowing rotational movement. Unlike traditional bearings, which are usually cylindrical or spherical, slewing bearings are designed with a wide diameter and are often customized for specific uses. They can support radial, axial, and moment loads simultaneously, making them versatile in various industrial applications.

Key Components of a Slewing Bearing

Slewing bearings are composed of several key parts, each playing a critical role in the bearing’s overall function and performance. Here’s a detailed look at the main components:

1. Outer Ring

The outer ring is one of the most important components of a slewing bearing. It serves as the stationary part of the bearing, housing the raceways that the rolling elements move along. The outer ring is typically made from high-quality steel to withstand significant loads and environmental conditions.

The slewing-bearing outer ring is often equipped with gear teeth on its inner or outer circumference, depending on the specific application. These teeth engage with a pinion to transmit rotational motion, allowing the machinery to rotate smoothly. The precision of the outer ring’s manufacturing directly impacts the performance and lifespan of the bearing, making it a critical element in the bearing’s overall design.

2. Inner Ring

The inner ring of a slewing bearing works in conjunction with the outer ring, forming the second raceway that guides the rolling elements. Unlike the outer ring, the inner ring typically rotates, allowing the machinery it supports to move. The inner ring must be designed to withstand similar loads and environmental stresses as the outer ring. It’s also crafted from durable steel, ensuring longevity and reliable performance.

3. Rolling Elements

The rolling elements within a slewing bearing are typically balls or cylindrical rollers, depending on the design. These components reduce friction between the inner and outer rings, allowing smooth rotational movement. The rolling elements are carefully spaced using separators, which help distribute loads evenly and prevent direct contact between them, reducing wear and tear. The type and size of the rolling elements are selected based on the bearing’s intended application, load capacity, and desired rotational speed.

4. Raceways

Raceways are the grooves on the inner surfaces of the inner and outer rings where the rolling elements move. The precision and quality of these raceways are crucial for the smooth operation of the slewing bearing. Any imperfections or deviations in the raceway surfaces can lead to increased friction, wear, and ultimately, bearing failure. The raceways are often hardened through heat treatment processes to enhance their durability and resistance to deformation under heavy loads.

5. Seals

Seals are essential components of a slewing bearing, protecting the internal parts from contaminants such as dirt, dust, and moisture. These seals are located between the inner and outer rings, ensuring that the rolling elements and raceways remain clean and lubricated. High-quality seals help extend the life of the bearing by preventing the ingress of harmful substances and retaining the lubricant inside the bearing.

6. Mounting Holes

The mounting holes in the inner and outer rings are used to secure the slewing bearing to the machinery it supports. These holes are precisely drilled to ensure proper alignment and load distribution. The number and size of the mounting holes vary depending on the bearing’s size and application, but they are essential for the stable operation of the bearing.

Conclusion

Slewing bearings are complex components that play a vital role in the functionality of heavy machinery. Each part of a slewing bearing, from the outer ring to the rolling elements and seals, is designed with precision to handle immense loads and provide smooth, reliable rotation. Among these, the slewing bearing outer ring is particularly significant, as it not only houses the raceways but also interacts with other machinery components to facilitate movement. Understanding the structure and function of these parts is essential for anyone involved in the design, maintenance, or operation of equipment that relies on slewing bearings.