What Size Are Slewing Rings?

2024-07-19

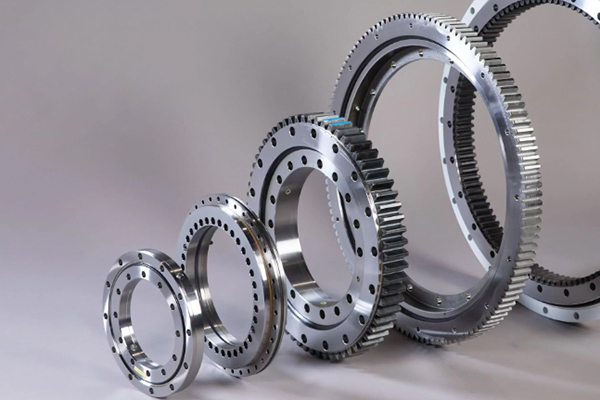

Slewing rings, crucial components in various industrial and machinery applications, play a pivotal role in facilitating rotational movement with minimal friction. However, determining the appropriate size of slewing rings can be a critical consideration, impacting the efficiency and longevity of equipment. Specific standards govern the dimensions of these rings to ensure compatibility and performance across different industries.

Understanding Slewing Rings:

Slewing rings, also known as turntable or slewing bearings, are essential in applications where there is a need for rotational movement between two machine elements. These components enable smooth rotation under heavy loads, making them indispensable in cranes, excavators, wind turbines, and medical equipment. The design of slewing rings allows for axial, radial, and moment loads to be accommodated simultaneously.

Slewing Ring Standardization:

To ensure interoperability and reliability across various applications, slewing rings adhere to international standards that specify their dimensions, load capacities, and performance criteria. One of the primary standards governing slewing rings is ISO 6124, which outlines the requirements for both the dimensions and testing methods of these bearings. These standards are crucial as they dictate the parameters that manufacturers must meet to guarantee the safety and efficiency of their products.

Key Parameters for Sizing:

When determining the size of a slewing ring, several key parameters come into play:

- Outer Diameter and Inner Diameter: These dimensions are critical as they dictate how the slewing ring will fit into the machinery and support the loads.

- Gear Options: Some slewing rings come with external or internal gears, affecting how they interface with the driving mechanism.

- Load Capacity: Understanding the expected loads (axial, radial, and moment) helps in selecting a slewing ring with an appropriate load capacity to ensure durability and reliability.

- Mounting and Installation: The method of mounting and installing the slewing ring can also influence the size selection to ensure proper fit and functionality.

Choosing the Right Size:

Selecting the correct size of the slewing ring involves careful consideration of the application requirements and adherence to standards. Engineers and designers must evaluate factors such as load conditions, rotational speeds, and environmental factors to determine the optimal size that will maximize performance and longevity.

Industry Applications:

Slewing rings find application in a wide range of industries:

- Construction and Mining: Used in cranes, excavators, and tunnel boring machines.

- Renewable Energy: Integral in wind turbines for azimuth and pitch rotation.

- Medical and Aerospace: Critical in MRI machines and satellite antenna positioning systems.

Conclusion:

In conclusion, the size of slewing rings is not arbitrary but governed by precise standards and application-specific requirements. Adhering to these standards ensures that slewing rings perform reliably under diverse conditions, contributing to the efficiency and safety of machinery across industries. As technology evolves, so too will the standards governing slewing rings, ensuring they continue to meet the demands of modern engineering and industrial applications.

By understanding the significance of sizing and standards, engineers and manufacturers can confidently select and integrate slewing rings that optimize performance and reliability in their respective fields.