Your Engineer’s Guide: Mastering Bearing Number Calculation and Design

2025-06-10

Selecting the right bearing for your machinery is more than just a simple purchase; it’s a critical engineering decision that impacts performance, reliability, and the bottom line. For procurement officers and company owners like Mark Thompson in the USA, navigating the world of bearing specifications can feel like deciphering a secret code. You know that finding a cost-effective solution from a global supplier is key, but you can’t afford to compromise on quality. The numbers and letters on a bearing aren’t random; they tell a story of size, load capacity, and purpose.

This article, written from my perspective as Allen, a factory owner in China specializing in bearing manufacturing, is designed to demystify that code. We will walk through the essential steps of bearing calculation and selection, from understanding a basic bearing number to calculating load ratings for specific applications. My goal is to bridge the gap between your procurement needs and the technical details your engineering team obsesses over. By the end, you’ll be equipped with the knowledge to lead more effective conversations with suppliers and make purchasing decisions with greater confidence.

What Do Bearing Numbers Actually Mean?

At first glance, a bearing number like "6205-2RS" seems cryptic. But think of it as a compact language. Every digit and letter in that sequence provides a specific piece of information about the bearing’s characteristics. This system, largely standardized by the International Organization for Standardization (ISO) and the American Bearing Manufacturers Association (ABMA), allows an engineer anywhere in the world to identify a bearing’s key features without needing a full-page specification sheet. It’s an efficient code for global industry.

The core of the bearing number typically defines the bearing type, the dimensional series (which relates bore size to outer diameter and width), and the bore diameter itself. Prefixes and suffixes are then added to indicate special features. For instance, a prefix might denote a specific component of a bearing (like a separable ring on a cylindrical roller bearing), while a suffix can describe the type of seal or shield used, the cage material, or specific internal clearance values. Understanding this structure is the first step toward making an informed selection. It’s the difference between guessing and knowing.

How Do You Identify the Basic Bearing Size from the Number?

The most fundamental piece of information you need is the bearing size, specifically the bore diameter (the inner hole). This determines if the bearing will fit on your shaft. For most standard metric bearings, the last two digits of the basic number reveal the bore size in millimeters (mm). It works like this:

- 00: 10 mm bore diameter

- 01: 12 mm bore diameter

- 02: 15 mm bore diameter

- 03: 17 mm bore diameter

- 04 and up: Multiply the number by 5 to get the bore diameter in mm.

Example:

For a bearing with the number 6208, the last two digits are 08.

08x 5 =40 mmbore diameter.

This simple calculation is a powerful starting point. When a client sends an inquiry with just a bearing number, this is the first thing my team decodes. It immediately tells us the scale of the application and helps us locate the right technical drawings and load ratings in our catalog.

| Basic Bearing Number Suffix | Bore Diameter (d) |

|---|---|

| …00 | 10 mm |

| …01 | 12 mm |

| …02 | 15 mm |

| …03 | 17 mm |

| …05 | 25 mm (5 x 5) |

| …10 | 50 mm (10 x 5) |

| …20 | 100 mm (20 x 5) |

What Are the Different Types of Bearing and How Do Numbers Differentiate Them?

Beyond size, the bearing number identifies the bearing type, which is critical for its performance. The primary distinction is between a ball bearing and a roller bearing, based on the shape of the rolling element. A ball makes point contact, ideal for high speeds but lower loads. A roller makes line contact, perfect for handling heavy loads.

The first digit or letter of the basic number often indicates the bearing type:

- 6xxx: Deep Groove Ball Bearing (the most common type of bearing).

- 7xxx: Angular Contact Ball Bearing.

- N, NU, NJ: Cylindrical Roller Bearings.

- 3xxxx: Taper Roller Bearings.

- 2xxxx: Spherical Roller Bearings.

Suffixes add more detail. For example:

- RS or 2RS: Indicates one or two rubber seals to keep contaminants out and grease in. This is a crucial feature for equipment operating in dirty conditions.

- Z or ZZ: Indicates one or two metal shields, which offer protection without adding rotational friction like a contact seal.

- C3 or C4: Denotes internal clearance greater than standard, necessary for applications with high temperatures or press fits where thermal expansion could cause the bearing to seize.

At our factory, we produce a wide variety of these, from a simple single-row ball bearing to complex E1144.30.12.D.3-RV Cylindrical roller bearing units. Each design is purpose-built, and the bearing number is the key to its specification.

How Do You Calculate the Required Load Capacity for a Bearing?

This is where we move from identification to true engineering. A bearing must be able to withstand the forces it will experience during operation. These forces, or loads, are categorized into two types:

- Radial Load (Fr): A force acting perpendicular to the shaft (like the weight of a belt pulling on a pulley).

- Axial Load (Fa): A force acting parallel to the shaft (a thrust load, like the force from a helical gear).

Most applications involve a combination of both. To simplify the selection process, bearing manufacturers use a calculation to determine a single, hypothetical value called the dynamic equivalent load (P). This value represents the constant radial load that a bearing could endure for the same life it would achieve under the actual combined load conditions. The basic formula is:

P = X Fr + Y Fa

Where:

- P is the dynamic equivalent load.

- Fr is the actual radial load.

- Fa is the actual axial load.

- X is the radial load factor.

- Y is the axial load factor.

The values for X and Y are not constant; they depend on the bearing type (ball vs. roller) and the ratio of axial to radial load. You can find these factors in any bearing manufacturer’s catalog. This calculation is the cornerstone of ensuring the bearing won’t fail prematurely under its expected working load. An incorrect load calculation is one of the most common reasons for bearing failure.

What is Bearing Rating Life (L10) and How is it Calculated?

Once you know the equivalent load (P), you can calculate the expected life of the bearing. Bearing life isn’t infinite; the repeated stress on the metal surfaces eventually leads to material fatigue. The standard for measuring this is the rating life (L10). The L10 life is the number of revolutions (or hours of operation at a constant speed) that 90% of a group of identical bearings are expected to complete or exceed before the first signs of fatigue appear.

The formula to calculate the L10 rating life is:

L10 = (C / P)^p

Let’s break that down:

- L10 is the rating life in millions of revolutions.

- C is the Basic Dynamic Load Rating. This is a value listed in the bearing catalog, representing the load a bearing can handle for one million revolutions. It’s a key measure of a bearing’s capacity.

- P is the dynamic equivalent load you calculated in the previous step.

- p is the life exponent:

p = 3for a ball bearing.p = 10/3(or 3.33) for a roller bearing.

This calculation is fundamental. If an application requires a bearing to operate for 20,000 hours, we use this formula to select a bearing with a C value high enough to meet that requirement under the given load (P). It’s all about matching the bearing’s stated capacity to the real-world demands of the machine.

What Factors Influence Bearing Selection Beyond Load and Speed?

While load and speed are the primary factors, the operating environment plays an equally important role in bearing selection and long-term reliability. A perfect load calculation means nothing if the bearing fails due to contamination or extreme heat. As a manufacturer, I always ask clients like Mark about the operating condition.

Key environmental factors include:

- Temperature: High temperatures can reduce the hardness of the bearing metal, degrade the lubricant, and cause thermal expansion that eliminates internal clearance. For these conditions, a bearing with higher clearance (like C3 or C4) and a special high-temperature grease may be required.

- Contamination: Dirt, dust, and moisture are enemies of any bearing. The choice between a non-contact metal shield (Z/ZZ) and a contact rubber seal (RS/2RS) depends on the severity of contamination. A shield is good for keeping out larger debris, while a seal provides better protection against fine dust and liquids, though it adds a small amount of rotational friction.

- Vibration and Shock Loads: Applications with heavy vibrations or sudden impacts (like in rock crushers or jackhammers) require a more robust bearing, often roller bearings, which have a higher load capacity and toughness compared to a standard ball bearing. The design must account for these peak loads, not just the average operating load.

How Does ISO Help in Bearing Selection?

For a global buyer, consistency is paramount. You need to know that a bearing from a supplier in China will have the same critical dimensions as one from Germany or the USA. This is where the International Organization for Standardization (ISO) comes in. ISO establishes globally recognized standards for bearing dimensions, tolerances, and terminology.

For example, ISO 15 outlines the boundary dimensions for radial rolling bearings. This standard ensures that a 6205 bearing from one manufacturer has the same bore diameter (25 mm), outer diameter (52 mm), and width (15 mm) as a 6205 from any other reputable bearing manufacturer. This interchangeability is the backbone of the global parts industry. When a supplier states their bearings are manufactured to ISO standards, it’s a promise of dimensional conformity and a baseline for quality. It’s a key detail I always emphasize because it gives my customers peace of mind.

Can You Explain the Calculation for a Taper Roller Bearing?

Taper roller bearings are special. Their conical design allows them to handle a combination of heavy radial and axial loads simultaneously, making them ideal for applications like vehicle wheel hubs and gearbox output shafts. However, their calculation is a bit more involved.

Because of their angled design, applying a pure radial load to a taper roller bearing induces an internal axial force. To counteract this, they are almost always used in pairs, mounted face-to-face or back-to-back. The calculation for the equivalent load (P) for a single taper roller bearing must account for this induced load. The formula still looks familiar:

P = X Fr + Y Fa

However, the determination of Fa is more complex. It must include both the external axial load and the induced load from the opposing bearing. The Y factor for a taper roller bearing is also dependent on a constant, e, found in the catalog. If the ratio Fa/Fr is less than or equal to ‘e’, the axial load is considered small, and the formula simplifies. If it’s greater than ‘e’, the full formula is used. This involves understanding how the two bearings in the pair share the overall load. It’s a slightly more complex puzzle, but one that ensures the exceptional performance of this bearing type is fully utilized.

What Information Should I Provide a Manufacturer for the Best Bearing Selection?

This is perhaps the most important question for a procurement officer. The quality of the bearing you receive is directly related to the quality of the information you provide. To avoid the frustration of shipping delays or receiving a part that doesn’t meet the specification, clear communication is essential. At my company, we’ve found that the process is smoothest when a customer can provide a complete picture of their application.

Here is a checklist of the information your engineer should provide to a bearing supplier:

- Dimensions:

- Shaft diameter (which gives the bearing bore diameter).

- Housing bore diameter (for the bearing outer diameter).

- Available width for the bearing.

- Loads:

- Magnitude of the radial load (Fr).

- Magnitude of the axial load (Fa).

- Are there any moment loads? (Critical for slewing rings).

- Are there shock loads or vibrations?

- Speed:

- The rotational speed (n), typically in revolutions per minute (RPM).

- Operating Conditions:

- The range of operating temperatures.

- The level and type of contamination (dust, water, chemicals).

- Lubrication requirements (grease or oil).

- Performance Requirements:

- The desired rating life (L10) in hours or revolutions.

- Any specific requirements for precision or rotational accuracy.

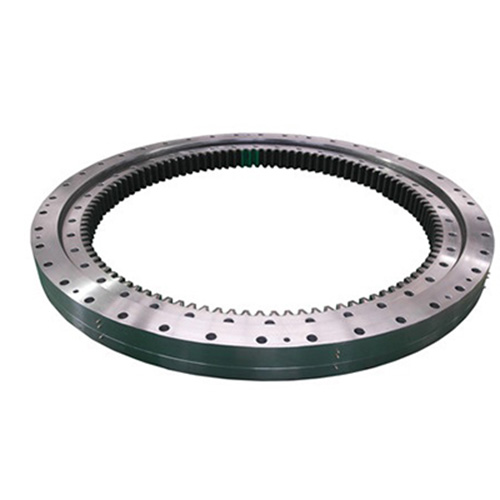

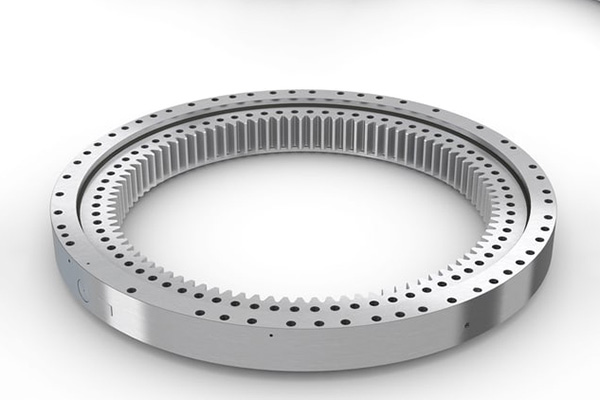

Providing this level of detail allows us to select or design the perfect bearing for your needs, whether it’s a standard deep groove ball bearing or a highly customized unit like our I.1100.22.00.A Precision slewing ring bearing.

How Can I Verify a Supplier’s Bearing Calculation and Quality?

Trust is built on verification. As a buyer located thousands of miles from your supplier, you need ways to confirm that their products meet your standards. This is a major pain point I’ve heard from many international clients who have had bad experiences elsewhere. A trustworthy bearing manufacturing partner should be transparent and willing to provide evidence of their quality.

Here are a few things you can and should request:

- Request a Technical Data Sheet: For the proposed bearing, ask for a specification sheet that lists the basic dynamic load rating (C), the static load rating (C0), and the X/Y factors. You can then have your engineering team double-check their life calculation.

- Ask for Material Certifications: The performance of a bearing depends heavily on the quality of the steel. Ask for a certificate that shows the chemical composition and hardness of the bearing metal. This ensures it meets industry standards for bearing-grade steel.

- Inquire About Quality Control: Ask about their inspection process. Do they provide dimensional inspection reports for each batch? Reputable suppliers like ourselves have rigorous QC protocols. For complex products, such as our 011.20.1220.000.11.1504 Precision double-row ball slewing ring, every single unit undergoes a strict inspection before shipping.

- Start with a Trial Order: Before placing a large volume order, consider a smaller trial order to test the product in your actual application. This is the ultimate test of performance and quality.

Building a relationship with a supplier involves more than just price negotiation; it’s about creating a technical partnership. Open communication and a willingness to share data are signs of a reliable High Quality Slewing Ring Bearings Supplier you can depend on for the long term.

Key Takeaways to Remember

Mastering bearing selection is a process of methodical evaluation. By focusing on the fundamentals, you can ensure you procure the right component for your equipment every time.

- Decode the Number: The bearing number is a code that tells you the bearing type, size, and special features. The last two digits (if 04 or higher) multiplied by 5 give you the bore diameter in mm.

- Calculate Your Loads: Determine the radial (Fr) and axial (Fa) loads of your application to calculate the dynamic equivalent load (P). This is the foundation of your entire selection process.

- Determine Required Life: Use the L10 life calculation, L10 = (C/P)^p, to select a bearing with a Basic Dynamic Load Rating (C) that will meet your operational lifespan requirements.

- Consider the Environment: Don’t forget temperature, contamination, and vibration. These conditions often dictate the need for specific seals, clearances, and lubricants.

- Communicate Clearly: Provide your supplier with a complete list of your technical requirements. The more detail you give, the better the product you will receive.

- Verify, Then Trust: Always ask for technical data sheets, material certifications, and quality reports to verify a supplier’s claims. A good partner will be happy to provide them.