The Ultimate Guide to Tower Crane Slewing Bearings: A Manufacturer’s Perspective

2025-06-17

A towering crane gracefully pirouetting against the city skyline is a common sight on any major construction site. But have you ever wondered what allows this massive piece of machinery to rotate so smoothly while carrying tons of material? The unsung hero is the tower crane slewing bearing. As a factory owner specializing in these critical components for over a decade, I’ve seen firsthand how the right bearing can make or break a project’s efficiency and safety. This guide is for procurement leaders like you, who need to understand not just what a slewing bearing is, but how to source a high-quality, reliable one that won’t lead to costly downtime or safety hazards. We’ll delve into the mechanics, manufacturing process, selection criteria, and maintenance, providing you with the knowledge to make informed decisions for your heavy machinery needs.

What Exactly is a Tower Crane Slewing Bearing?

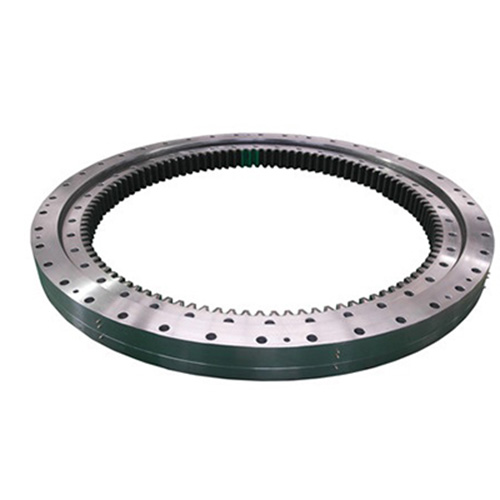

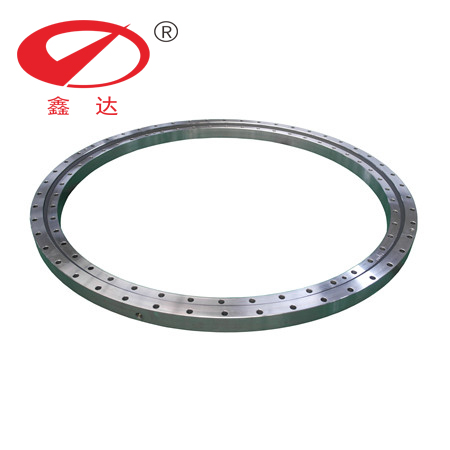

At its core, a tower crane slewing bearing is a large, circular bearing that creates a rotatable connection between the crane‘s upper structure—which includes the jib, counter-jib, and operator’s cabin—and the stationary mast or tower. Its primary job is to manage a complex combination of load forces. This isn’t just simple weight; it includes downward force (axial load), side forces from wind (radial load), and the significant tilting moments created by the outstretched jib and its payload. It is this single component that enables the crane to rotate horizontally, a movement technically known as slewing. This controlled rotation is fundamental for a tower crane to perform its main function: to lift and move heavy loads across different areas of a construction site.

Structurally, a tower crane slewing bearing consists of two concentric rings: an inner ring and an outer ring. In a typical crane setup, one ring is bolted to the lower structure (the mast), while the other supports the rotating crane’s upper structure. Nestled between these rings are the rolling elements, which can be precisely engineered balls or rollers. These elements are the heart of the smooth movement, drastically reducing friction to enable the effortless rotation of the crane. To power this movement, the rings often feature gear teeth on either the inner or outer diameter. These teeth engage with a drive pinion from the crane‘s motor, allowing for powered rotation. This crucial part, also known as a slewing ring, is meticulously designed to withstand heavy loads and ensure the crane operates with utmost safety and efficiency.

How Does the Slewing Mechanism Function in a Tower Crane?

The slewing mechanism is the entire system responsible for the horizontal rotation of the entire structure of the tower crane. It’s a symphony of powerful components working in harmony, consisting of the slewing bearing, one or two powerful motors, a reduction gearbox, and a drive pinion. The process begins with the motor, which generates the rotational force. This force is amplified and slowed through the gearbox before being transmitted to the drive pinion. This hardened pinion then meshes perfectly with the gear teeth on the slewing bearing, causing the crane’s upper structure to rotate smoothly around the stationary mast. In this system, the bearing acts as the central pivot, flawlessly transferring all operational loads from the massive rotating section down to the fixed tower.

This entire process demands more than just brute strength; it requires immense precision. The quality of the slewing bearing directly dictates the smoothness and accuracy of the crane‘s movement. A well-manufactured bearing, built with minimal internal clearance and backlash, allows the operator to position the hoist and load with pinpoint accuracy. This is critical when navigating tight spaces on a busy construction site. The entire system is engineered for smooth operation, a feature that is vital not only for project efficiency but, more importantly, for the safety of the entire crew below. Any sudden jerking or uneven movement can introduce dangerous stress on the crane, its components, and the load it carries.

Why is the Slewing Bearing So Critical for Tower Crane Operations?

The slewing bearing is, without exaggeration, one of the most critical components of any tower crane. Consider this: the entire weight of the crane’s upper section, combined with the heavy loads it is designed to lift, rests entirely on this single component. Its failure wouldn’t just halt operations; it could lead to a catastrophic structural collapse, endangering the lives of everyone on the construction site. This is precisely why its load capacity and structural integrity are paramount and subject to rigorous engineering and testing. The bearing must simultaneously manage immense downward force (axial load), side forces from wind and movement (radial load), and the massive leverage or tilting moment created by a long jib carrying a heavy load.

Beyond the obvious safety implications, the slewing bearing plays a crucial role in the crane‘s day-to-day operational efficiency and longevity. A high-quality bearing guarantees smooth rotation, which in turn reduces wear and tear on the entire drive system and minimizes the energy required to power the slewing motion. Conversely, a faulty or worn bearing can lead to increased friction, jerky movements that strain the structure, and costly, unscheduled downtime for repairs. These disruptions directly impact project timelines and budgets. Therefore, investing in a durable, properly maintained slewing bearing is a strategic decision that lowers long-term maintenance costs and significantly extends the service life of the crane. The overall reliability of the crane is inextricably linked to the reliability of its bearing.

What Are the Different Types of Bearings Used in Tower Cranes?

While their fundamental function remains the same, not all tower crane slewing bearings are built alike. The specific type of bearing chosen for a crane depends on its size, lifting capacity, and the specific demands of its application. The most common types you will encounter are:

- Single-row four-point contact ball bearing: This is the workhorse of the industry, commonly found in light to medium-duty tower crane models. Its ingenious design allows a single row of balls to handle axial, radial, and moment loads simultaneously, making it a highly versatile and cost-effective solution.

- Single-row crossed roller bearing: These bearings feature cylindrical rollers arranged in a crisscross pattern. This configuration provides greater contact area, resulting in higher rigidity and rotational accuracy compared to ball bearings. They are often used in cranes that require more precise positioning.

- Double-row ball bearing: As the name suggests, this design incorporates two rows of steel balls. This effectively doubles the number of contact points, giving it a significantly higher load capacity than a single-row bearing. It’s a common choice for larger tower cranes that handle heavier materials.

- Three-row roller bearing: This is the heavyweight champion of slewing bearings. It utilizes three independent rows of rollers, with each row engineered to handle a specific type of load (axial, radial, and moment). This makes it the ideal choice for the largest and most powerful tower cranes, as well as other heavy machinery like port cranes, that are designed to handle the most extreme heavy loads.

To help procurement professionals like you, Mark, make a quick assessment, here is a simple comparison table:

| Bearing Type | Load Capacity | Cost | Common Application in a Crane |

|---|---|---|---|

| Single-Row Ball | Moderate | Low | Small to Medium Tower Cranes |

| Double-Row Ball | High | Medium | Medium to Large Tower Cranes |

| Single-Row Roller | High | Medium-High | Cranes requiring high precision |

| Three-Row Roller | Very High | High | Heavy-duty Tower Cranes, Port Cranes |

This table illustrates that for most standard tower crane applications, a single-row or double-row ball bearing provides the right balance of performance and cost. However, for exceptionally heavy-duty tasks, roller bearings are essential to safely manage the higher loads.

How Are High-Quality Tower Crane Slewing Rings Manufactured?

As a direct supplier and manufacturer of these essential components, I can assure you that the manufacture of a high-quality tower crane slewing bearing is an exacting science. The process is meticulous from start to finish, beginning with the uncompromising selection of raw materials. We use high-grade steel alloys like 42CrMo or 50Mn, and every batch must come with a certificate of authenticity. This steel is then forged into seamless rings, a critical step that aligns the internal grain structure of the metal to provide maximum strength and fatigue resistance.

After the initial forging, the rings embark on a journey through several critical manufacturing stages:

- Rough Machining: The raw forged rings are shaped into their initial form, creating the basic geometry of the inner and outer rings.

- Heat Treatment: This is arguably the most crucial step for durability. The raceways—the hardened paths where the rolling elements travel—are subjected to precision induction hardening. This creates a surface that is extremely resistant to wear while keeping the core of the ring ductile. The gear teeth undergo a similar hardening process.

- Finish Machining & Grinding: In this stage, precision is key. The raceways, gear teeth, and mounting surfaces are ground to achieve extremely tight dimensional tolerances and a mirror-smooth finish, which is essential for low-friction rotation.

- Drilling: The mounting holes are drilled with computer-controlled machinery to ensure perfect alignment when installing the bearing on the crane.

- Assembly: The rolling elements (balls or rollers) and their cages or spacers are carefully placed between the rings and allow for movement. High-performance seals are then installed to keep essential grease in and harmful contaminants out. Finally, the bearing is assembled and pre-loaded to the correct internal clearance.

- Final Inspection: Before a bearing earns our stamp of approval, it undergoes a battery of rigorous tests. We check for dimensional accuracy, rotational torque, and running clearance to ensure it meets or exceeds all relevant industry standards.

What Should You Look for When Choosing a Slewing Bearing Supplier?

Choosing the right supplier is every bit as important as choosing the right bearing. As a procurement officer, you’ve likely experienced the frustration of communication barriers or receiving products of inconsistent quality. The key is to look for a supplier of tower crane slewing bearings that demonstrates deep expertise and complete transparency. Do they have engineers on staff who can discuss technical drawings and load calculations? Will they willingly provide material certifications and heat treatment reports for your order? A reputable supplier will not only expect these questions but will have the answers ready.

To help you vet potential partners, here is a checklist of attributes to look for in a supplier:

- Technical Expertise: Their team should be able to do more than just quote a price. They should be able to discuss your specific load requirements and even assist with custom designs if needed.

- Proven Track Record: Don’t hesitate to ask for case studies or client references, particularly from companies in your region (USA, North America, Europe, etc.).

- Quality Certifications: ISO 9001 certification is the baseline standard, indicating that the manufacturer has a robust and repeatable quality management system in place.

- Transparent Communication: You need clear, prompt answers from sales representatives who truly understand the product. This is the antidote to the common pain point of inefficient communication.

- Comprehensive Documentation: A trustworthy supplier will readily provide all necessary documentation, from material certificates to final inspection reports, ensuring you have a complete quality record.

- Lead Time Reliability: Inquire about their production capacity and realistic lead times. An honest factory will provide you with achievable timelines, helping you avoid production schedule disruptions. We, for example, pride ourselves on our robust production lines that can deliver products like our I.1100.22.00.A Precision slewing ring bearing on schedule.

How Do You Verify the Load Capacity and Quality of a Bearing?

You should never have to take a supplier‘s claims at face value. The quality and load capacity of a tower crane bearing can and should be independently verified. The most fundamental method of verification is through thorough documentation. Before you even place an order, the manufacturer should be able to provide detailed calculations, often based on Finite Element Analysis (FEA), that prove the bearing is designed to withstand heavy loads as specified for your particular crane model.

Before finalizing any purchase, insist on receiving this package of key documents:

- Material Certificate: This legal document confirms that the steel alloy used for the inner and outer rings (e.g., 42CrMo) meets the required international standard.

- Heat Treatment Report: This report details the resulting hardness and depth of the hardened layer on the raceways and gear teeth. This data is a direct indicator of the bearing‘s future wear resistance and longevity.

- Dimensional Inspection Report: This report is a comprehensive list verifying that all critical dimensions—including the diameter, height, concentricity, and mounting hole positions—are within the strict tolerances defined on the engineering drawing.

- UT/MT Reports: For high-stakes applications, you can request reports from Ultrasonic Testing (UT) or Magnetic Particle Testing (MT). These non-destructive tests confirm that there are no hidden cracks or flaws within the forged steel rings.

A trustworthy supplier will have these documents readily available. Our Precision double-row ball slewing ring products, for instance, are always shipped with a complete documentation package to provide our clients with total confidence and traceability.

What are the Key Maintenance Practices for a Tower Crane Slewing Bearing?

Once you have procured and installed a high-quality bearing, a disciplined maintenance routine is the key to achieving optimal performance and a long, trouble-free service life. Neglecting maintenance on a component as critical as a tower crane slewing bearing is a gamble no one should take. The two pillars of effective maintenance are lubrication and inspection. Proper lubrication is the lifeblood of the bearing; it minimizes friction, prevents corrosion, and helps dissipate the heat generated during rotation.

Here is a standard maintenance schedule that should be rigorously followed for any tower crane:

- Regular Lubrication: The raceway must be re-lubricated with the correct type and grade of grease at the intervals specified by the manufacturer. This is typically every 50-100 operating hours for a crane. The gear teeth require a separate, more viscous lubricant designed to adhere to open gears.

- Torque Checks: The high-strength mounting bolts that secure the bearing to the crane‘s structure can gradually loosen over time due to constant vibration. They must be checked and re-torqued periodically to the manufacturer’s precise specifications. This is a simple but critically important safety check.

- Seal Inspection: Visually inspect the rubber seals for any signs of damage, cracking, or excessive wear. Damaged seals are an open invitation for contaminants like dust, debris, and water to enter the raceway, which will rapidly degrade the bearing and lead to premature failure.

- Rotational Check: During normal operation, the crew should always be alert to any unusual grinding, popping, or clicking noises. The process of the crane to rotate should be nearly silent and exceptionally smooth. Any audible change is an early warning sign of a developing problem.

- Wear Measurement: Technicians should periodically measure the rock or tilt clearance of the bearing to monitor its internal wear. Most manufacturers provide a specific procedure for this, often called a "rock check." A measurable increase in this clearance over time is a clear indicator of wear in the raceway.

What are the Common Signs of Slewing Bearing Wear and Failure?

Learning to recognize the early signs of wear can empower you to schedule maintenance or order replacement spare parts long before a catastrophic failure occurs. This proactive approach is the best way to prevent dangerous situations and costly, unplanned downtime. For a piece of equipment like a tower crane, these warning signs must be taken seriously and addressed immediately.

Here are the most common signs that a slewing bearing is nearing the end of its life:

- Unusual Noises: This is the most frequent and obvious indicator. Grinding, clicking, or popping sounds during the rotation of the crane almost always signal a problem. This could be due to damaged rolling elements, a lack of lubricant, or a contaminated raceway.

- Increased Rotational Torque: If the slewing motor appears to be straining or drawing more electrical current than usual to rotate the crane, it is a sign of increased friction within the bearing.

- Jerky or Uneven Rotation: A lack of smooth rotation is a very serious red flag. It indicates significant wear, "denting" of the raceway, or internal damage within the bearing that is impeding movement.

- Metal Shavings: Finding small, glitter-like metal particles in the old grease that is purged from the bearing during re-lubrication is a definitive sign of internal metal-on-metal wear and component degradation.

- Excessive Play or Tilting: If the crane’s upper structure feels noticeably loose or tilts more than it should when a load is applied, the bearing is likely severely worn out. This creates an unstable condition and is a critical safety issue that demands the crane be taken out of service immediately.

If you observe any of these signs, it’s imperative to conduct a thorough inspection and begin the process of sourcing a reliable replacement, such as a high-quality INA Slewing Bearing or equivalent.

How to Ensure Proper Installation of a Tower Crane Slewing Bearing?

All the diligent effort you put into selecting and procuring a high-quality bearing can be completely undone by a flawed installation process. Proper installing is the final, critical step to ensure the safe, reliable, and long-term operation of the tower crane. This complex task should only be performed by experienced, qualified technicians during the crane‘s initial erection or during a major overhaul.

Here are the essential best practices for a successful installation:

- Clean and Flat Mounting Surface: The steel surfaces on both the upper structure and lower structure where the bearing will be mounted must be perfectly clean, dry, and, most importantly, flat. They must be free of any burrs, old paint, rust, or debris. Any surface unevenness will distort the precision-ground bearing when it is bolted down, leading to concentrated stress points and certain premature failure.

- Correct Orientation: The slewing bearing will have markings indicating the "soft spot" (the point of lowest radial runout). This spot should be aligned according to the crane manufacturer’s instructions, typically positioned in the area of lowest load to maximize the bearing‘s life.

- Use New, High-Strength Bolts: Always use a new set of high-strength bolts of the correct grade (e.g., Class 10.9) and length as specified by the manufacturer. Never reuse old mounting bolts, as they can be stretched and fatigued.

- Systematic Tightening Pattern: The bolts must be tightened in a specific star or criss-cross pattern, not in a circle. This should be done in multiple stages (e.g., 30%, 70%, 100% of final torque) to apply even clamping pressure across the entire bearing ring.

- Apply Correct Torque: Use a calibrated torque wrench to tighten each bolt to the exact torque value specified by the manufacturer. Both over-tightening and under-tightening are dangerous and can lead to bolt failure or an insecure bearing.

- Final Checks: After installation is complete, manually check the rotational torque to ensure the bearing turns smoothly without binding. It’s also best practice to re-check the bolt torque after the first few hours of the crane‘s operation.

Key Takeaways

The tower crane slewing bearing is far more than just a simple part; it is the linchpin that ensures the safety, efficiency, and reliability of your most vital lifting machinery. For procurement managers and business owners like Mark, understanding the nuances of this component—from its manufacture to its maintenance—is key to mitigating risk and maximizing the return on your equipment investment. By partnering with a knowledgeable and transparent supplier, you can ensure you receive a bearing that not only meets but exceeds the demands of the modern construction site.

Here are the most important things to remember:

- Function is Critical: The slewing bearing supports the entire weight of the crane‘s upper section and its load, enabling the crucial horizontal rotation needed for all lifting operations.

- Quality is Non-Negotiable: The manufacturing process, from material selection to heat treatment and final grinding, determines the bearing‘s performance and lifespan. Always demand full documentation.

- Choose Your Supplier Wisely: Look for a partner with technical expertise, a proven track record, and a commitment to transparent communication to avoid common procurement pain points.

- Maintenance is Mandatory: Regular lubrication, bolt torque checks, and visual inspections are essential to prevent downtime and ensure the crane operates safely.

- Installation Matters: A perfect bearing can fail if installed incorrectly. Ensure mounting surfaces are flat and that proper bolt tightening procedures are followed by qualified personnel.